During my Blazing Paddles brewday I had a loss of power caused by the failure of one of the main cabinet switches that powers the HLT pump and element. I quickly replaced it like for like with a 16A switch I had laying around and finished my brew.

Later on I began to get a bit worried about these switches. They're rated at 20A/125V & 16A/250V which to me means they should be able to handle the load. But then I started thinking about the nature of that load. As the BrewPi/BrewBlox brewery control system I use utilises software PIDs to drive Solid State Relays that control power to the elements via Pulse Wave Modulation, these switches are continuously being cycled through 100% load, then 0% load over a matter of a few seconds depending on how much heat is required to hit the target temp.

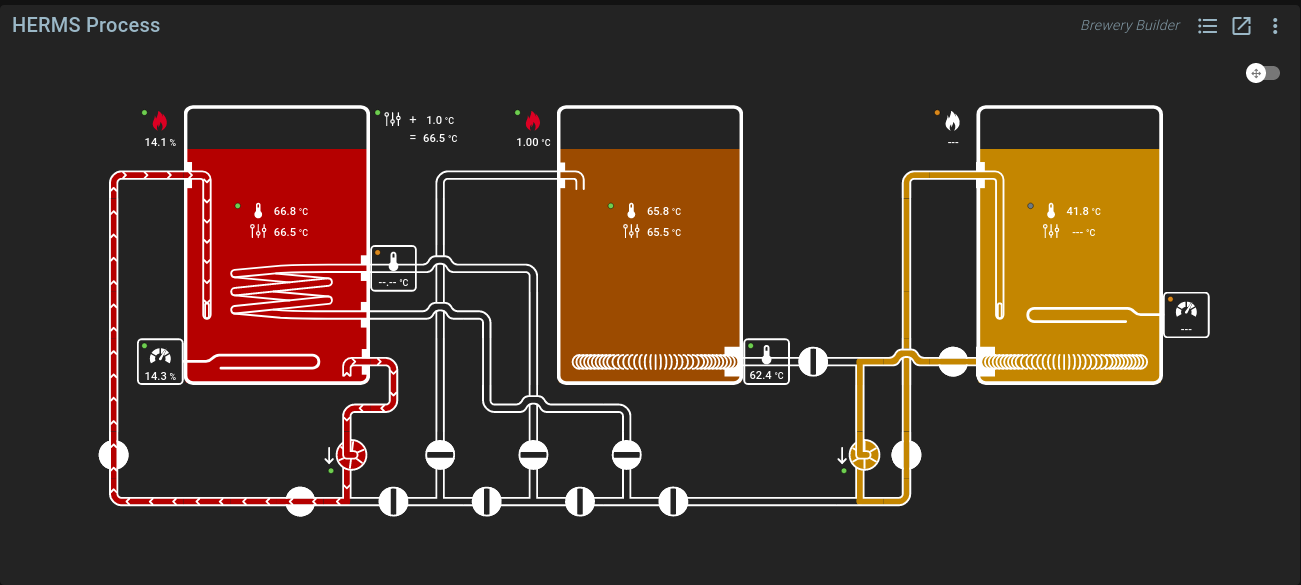

In the example below, the HLT element (lower left) is being driven at 14.3% which means the SSR will close the circuit for 14.3% of 4 SEC (the default PWM window) or 0.572 seconds and leave the circuit open for 3.428 seconds in a continuous cycle until it approaches the target temp.

Thinking this through it's pretty clear that all this in-rush, out-rush of current surging across a small contact area is bound to generate some heat, and these switches may not be rated for that kind of non-continuous load.

I dug around a little and was eventually advised that switches are rated in a number of different ways...'absolute current it can handle, absolute breakdown voltage, and power it can transfer (V * I), etc', and that 'elements can generate significant voltage and current spikes when switched on while they heat up and reach maximum impedance'.

Solution

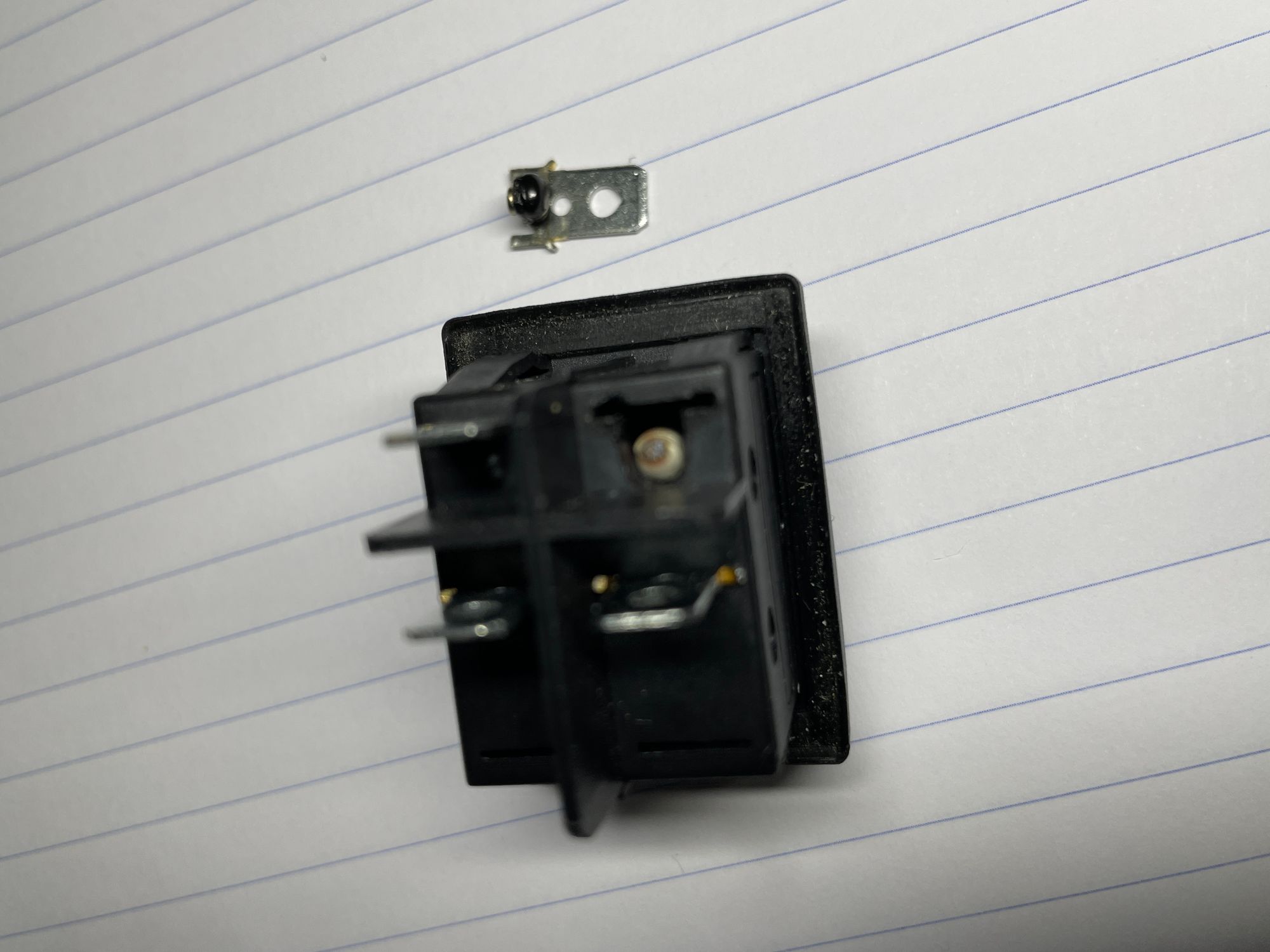

Bigger switches seems like a bit of a no-brainer, so I have simply replaced the lightweight 16A switches with some beefier 20A switches that are rated for high inductive loads like motors that cause power surges like the PWM switching does. You can see that the contact area alone is 10 times larger than the cheap 16A switches I used previously and the materials are much heavier too.

Problem solved, I hope.