As Blazing Paddles ended at around 8.3%ABV, it's not what you'd call a session ale by any stretch so I decided that before I brew another Schofferhoffer Weizen Clone, I should brew another lower ABV IPA that I can drink more than 2 glasses at a time before falling over. There's many sources for recipes, but not many have the detailed brewing notes that you'll find with Electric Brewery Recipes.

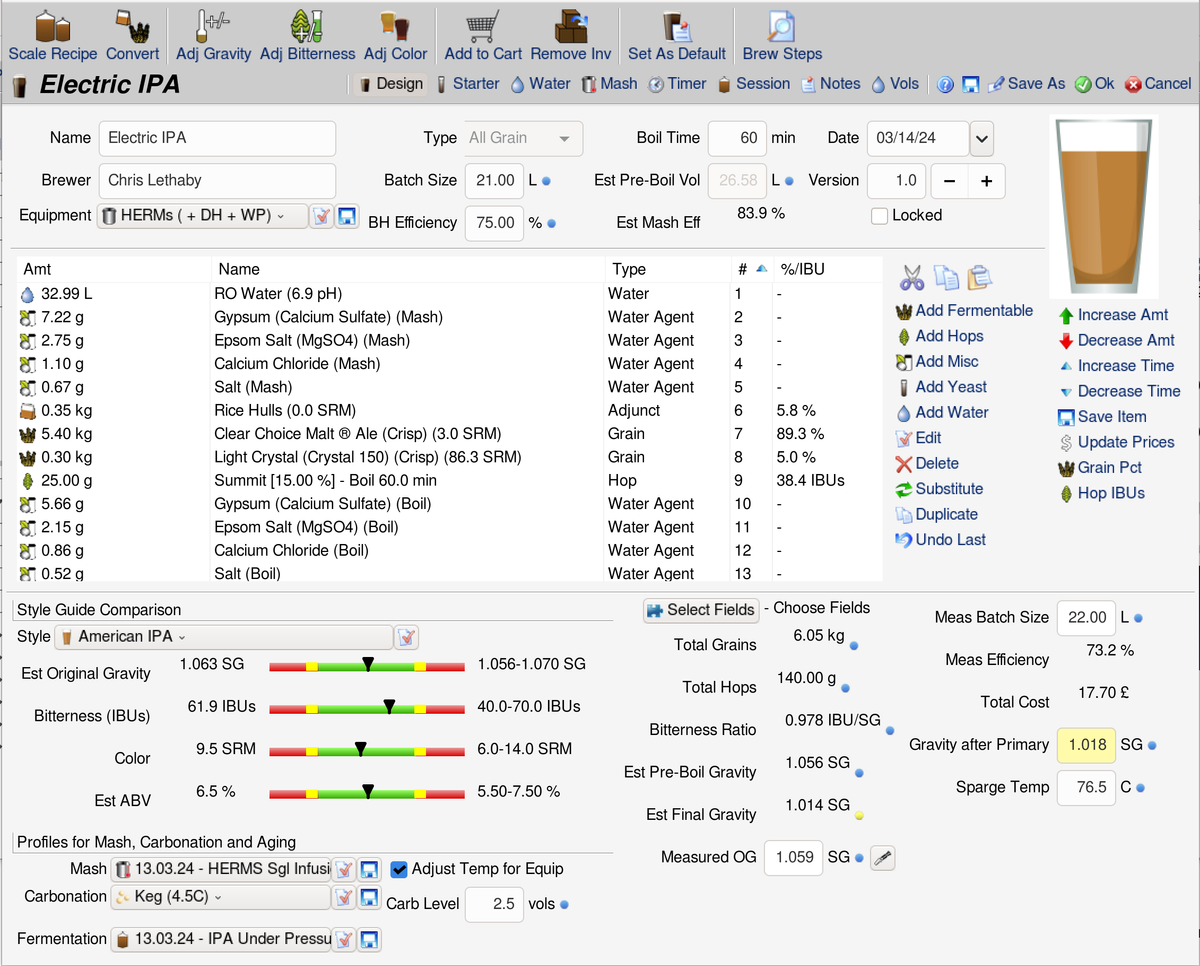

After reviewing them I settled on the Electric IPA as it uses hops I haven't tried before and has great reviews, so I converted all the measurements and typed up a recipe in Beersmith keeping all the ratios, IBU's etc as documented in the original 12 Gal recipe

Recipe

I copied the original as faithfully as I could electing to use Crisp's Clear Choice Malt in place of American domestic 2-Row, and Crisp's Crystal 150 to match the 50-60 lovibond Crystal Malt specified in the original recipe.

The only significant change I made was substituting Warrior for Summit bittering hops. You may also notice that I used less hops in the hot side of the recipe based on a strict 12gal:5gal ratio but stuck as close as I could to the prescribed IBU's instead.

Target Batch size: 21.0 liters (into fermenter)

Brewhouse efficiency: 75% (increased since Blazing Paddles)

Target OG: 1.063

Target FG: 1.014

Est IBUs: 61.9

Est ABV: 6.5

MALT/GRAIN BILL

5.4 Kg Crisp's Clear Choice Malt - std crush

0.3 Kg Crisp's Crystal 150 - std crush

0.30 Kg Rice Hulls

WATER PROFILE

Hoppy

Profile: Ca=110, Mg=18, Na=16, Cl=50, SO4=275

Description: High SO4 with restrained Cl which helps accentuate hop bitterness / dryness. For hoppy American styles

HOPS & ADDITIONS SCHEDULE

25g Summit (15%) - 60 min (Boil)

25g Centennial (9.6%) - 5min (Boil)

20g Amarillo (9.9%) - 5min (Boil)

35g Citra (12.1%) - 5 gravity points before fermentation ends (3 days)

35g Crystal (3.3%) - 5 gravity points before fermentation ends (3 days)

YEAST

WHC Labs LAX - 2 x 11g sachets

Brewday

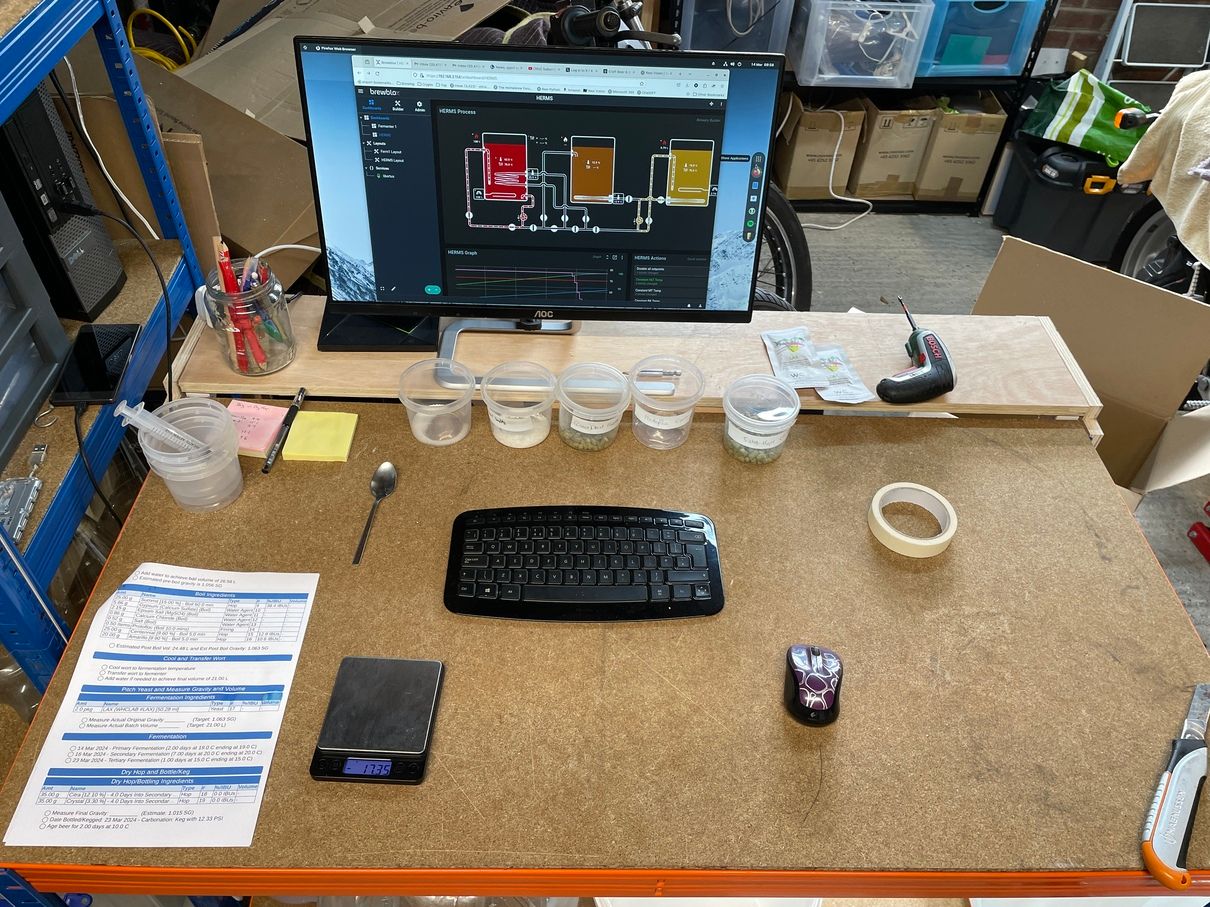

My Brewday started the day before with making some RO water.

- 26 l for the HLT (enough to cover the HERMS) coil and then use 14l to sparge

- 18.5 l into the BK to mash in with

9am on Thursday 14th I turned the power on and and set the target temp for the BK to 76.6 degrees for the mash water, and 70.5 degrees for the HLT. This is 3 degrees higher than the recipe's mash temp as I wanted to be ready to use the HERMS coil to add heat if I undershot. If I overshot I had some cold RO water on hand to cool the mash down.

Then I measured out all the water and hop additions. NB: I hold the sparge water salts until the boil.

Mash-In

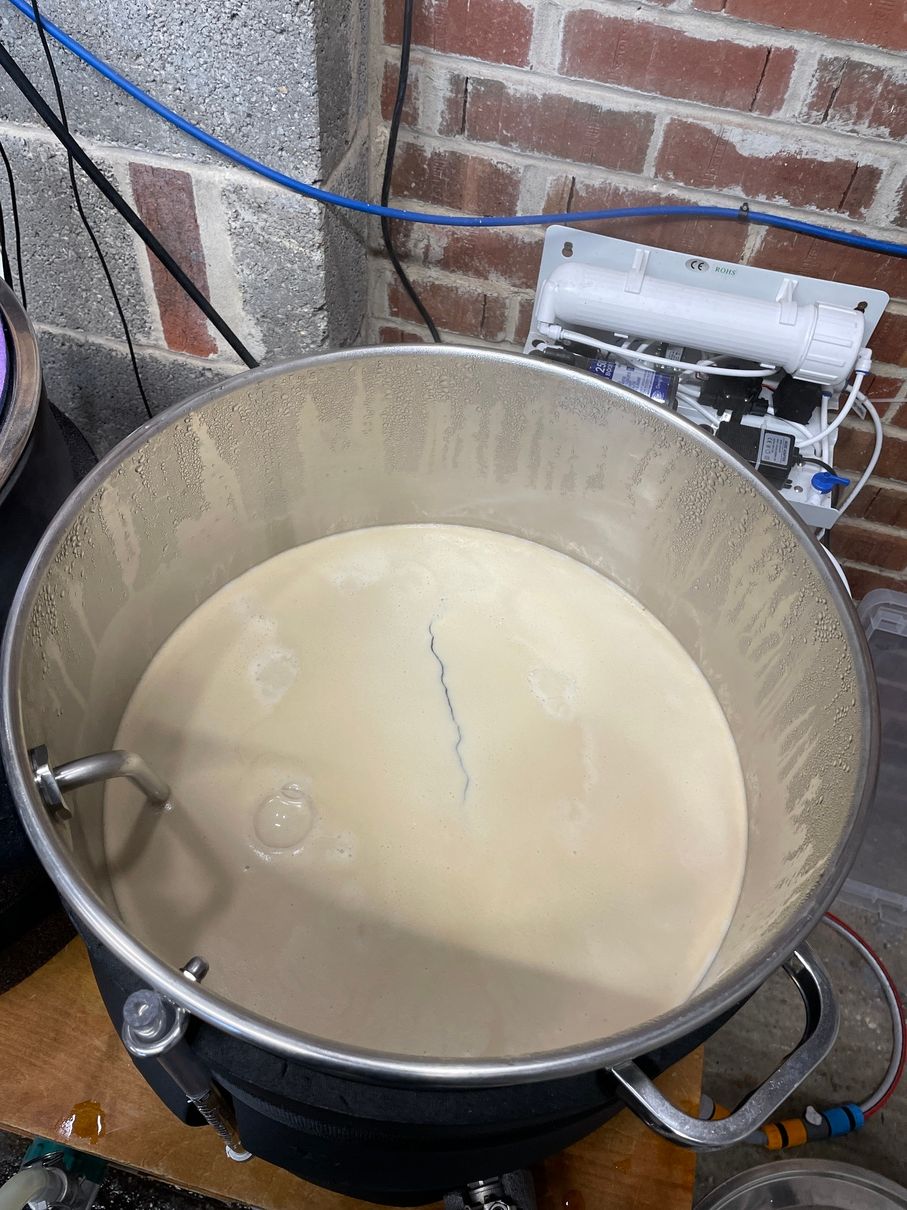

Once the water was heating, I then proceeded to layer all the malts and rice hulls in the Mash Tun, so that when the mash water hit target temp at 10.05am I mashed in straight away by underletting. I then stirred like crazy for 5 minutes, let the wort settle a bit checked the temperatures. and took a pH reading.

pH was 5.5 and my mash temp was perfect.

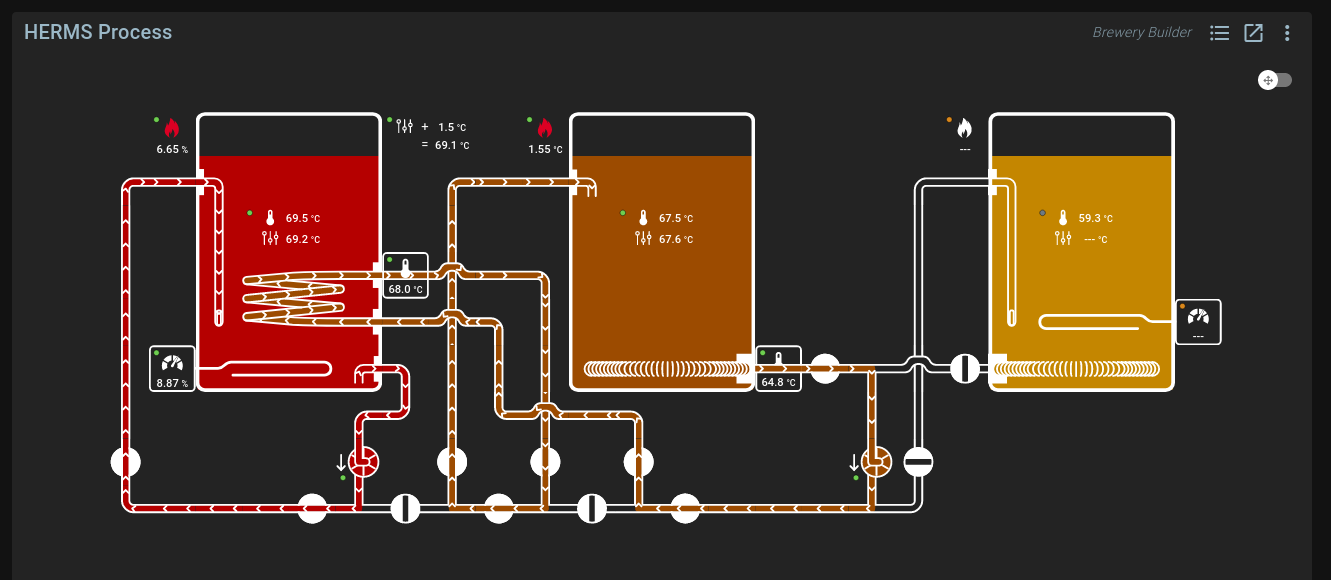

After another healthy stir and a minute to settle I then attached the recirculation manifold and started my HERMS recirculation/vorlauf, and after a few minutes I had beautiful clear wort recirculating at 67.6c. Note the cooler temp of 64.8C at the MT exit compenstated for by the warmer 68.0C leaving the HERMS coil after it's picked up heat from the 69.5C water in the HLT.

Managing the Mash temp via HERMS using my new recirculation manifold.

From here, the rest of the mash and the boil went as planned with no major issues. After mashing for an hour I raised the temp to 76C over 15 minutes and began pumping out the wort into the BK. Once it contained 13 litres I began slowly sparging with 14l of RO water from the HLT at 76.6C. After 40 minutes the final sparge runnings measured 1.020 but it was still time to stop.

Sparging

Boil

After recovering all the sparge water from the MT I had overshot the target BK vol by 1.2l which meant I started the boil with no bittering hops at the beginning and only added these when the boil vol matched my original boil target. I then added the 60min bittering hops and continued to boil using my Steam Condenser to capture all the steam for 1 hour following the original hop addition schedule to end up hitting my post boil volume of 24.5l perfectly. 1/2 Protofloc was added at 10min with the hot-side flavour hops added at 5min as planned.

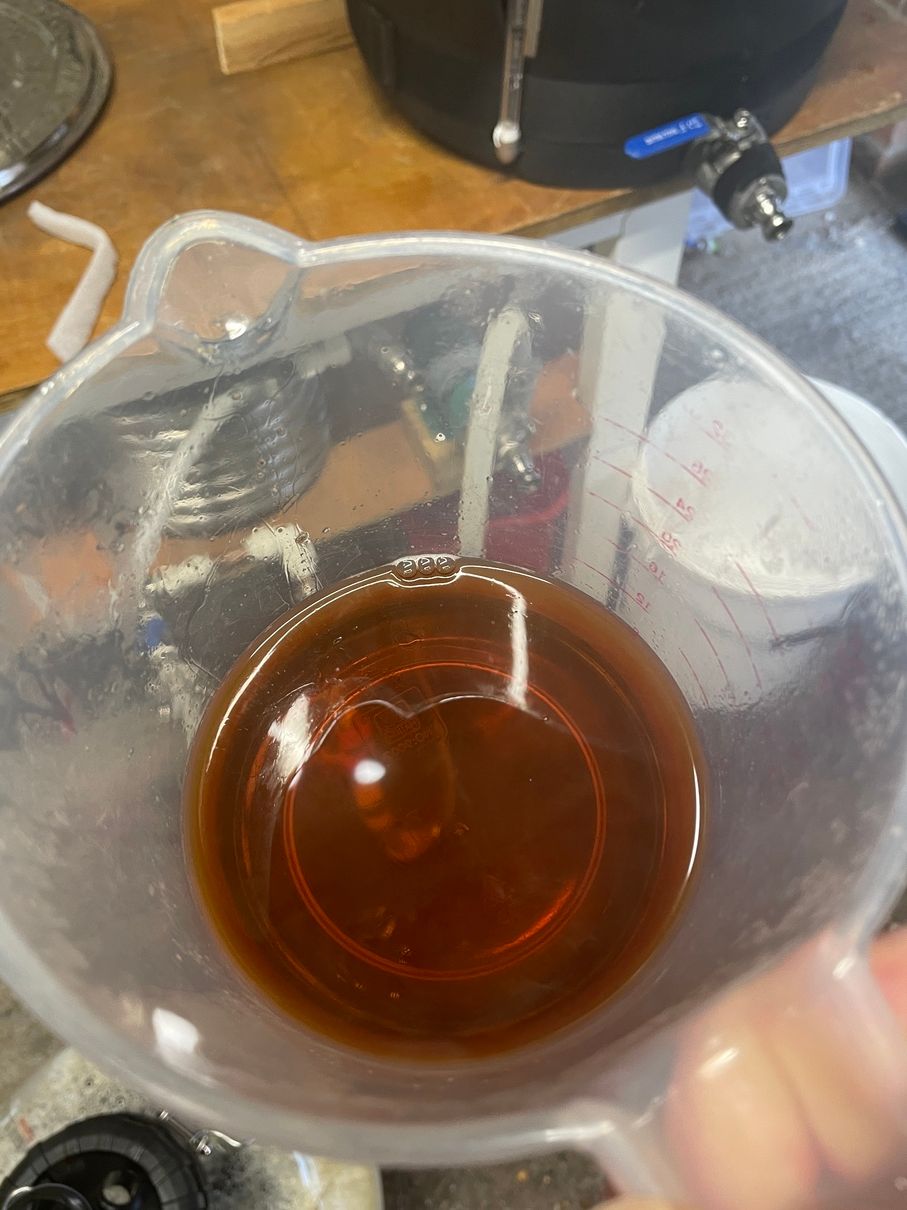

The recipe did not call for a whirlpool so the wort was rapidly chilled through my counterflow chiller into one of my Fermzilla All-Rounders.

OG = 1.059 missing the 1.063 target by 4 points. I put this down to failing to order Fine Crush for the malts which has previously enabled me to increase my Brewhouse Efficiency from 72 to 75%.

Fermentation

Once the wort was in the fermenter it went into my fermentation fridge where it was still showing as being 24C so I waited 5 hours until 8:30pm and then sprinkled the yeast at 19C.

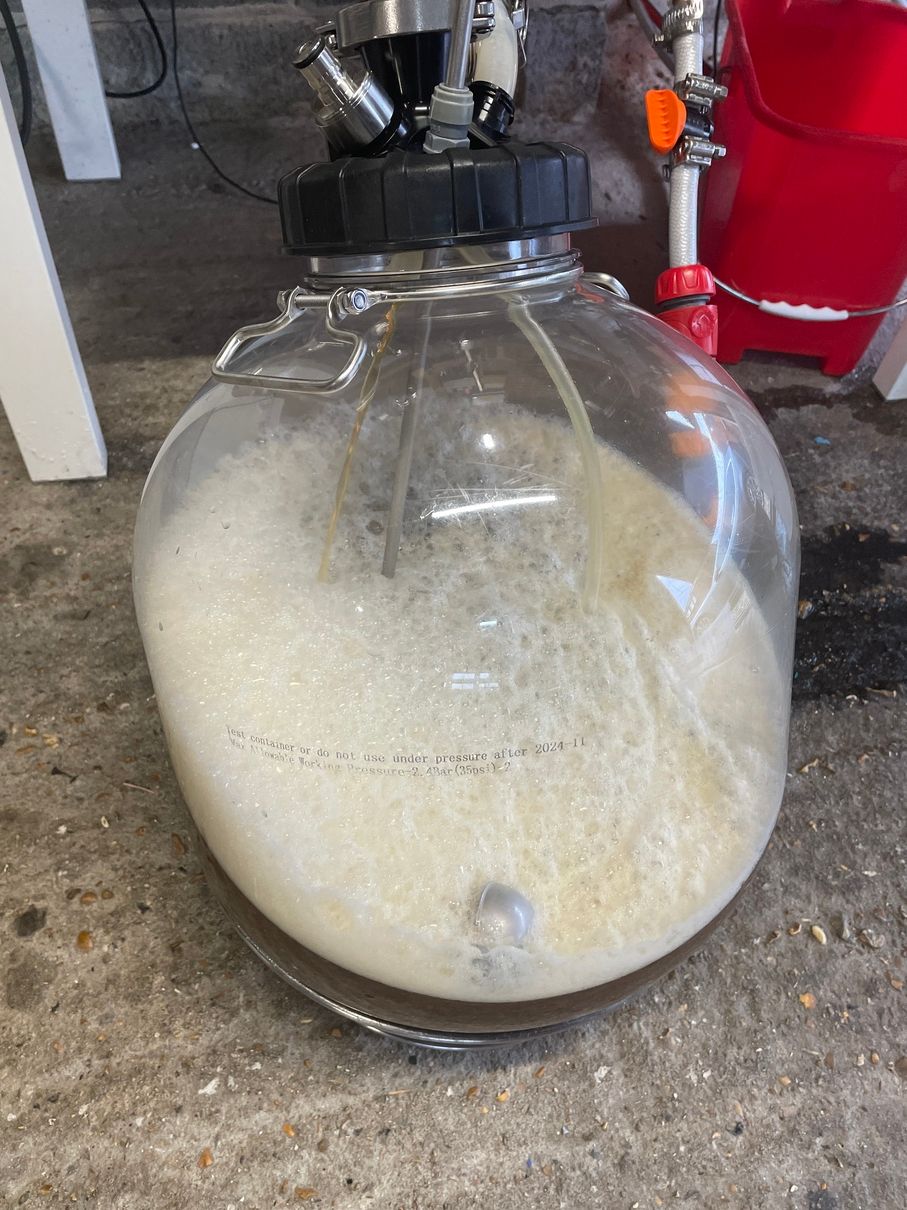

24 hours later it has started to take off and another 24 hours later it had formed a high krausen.

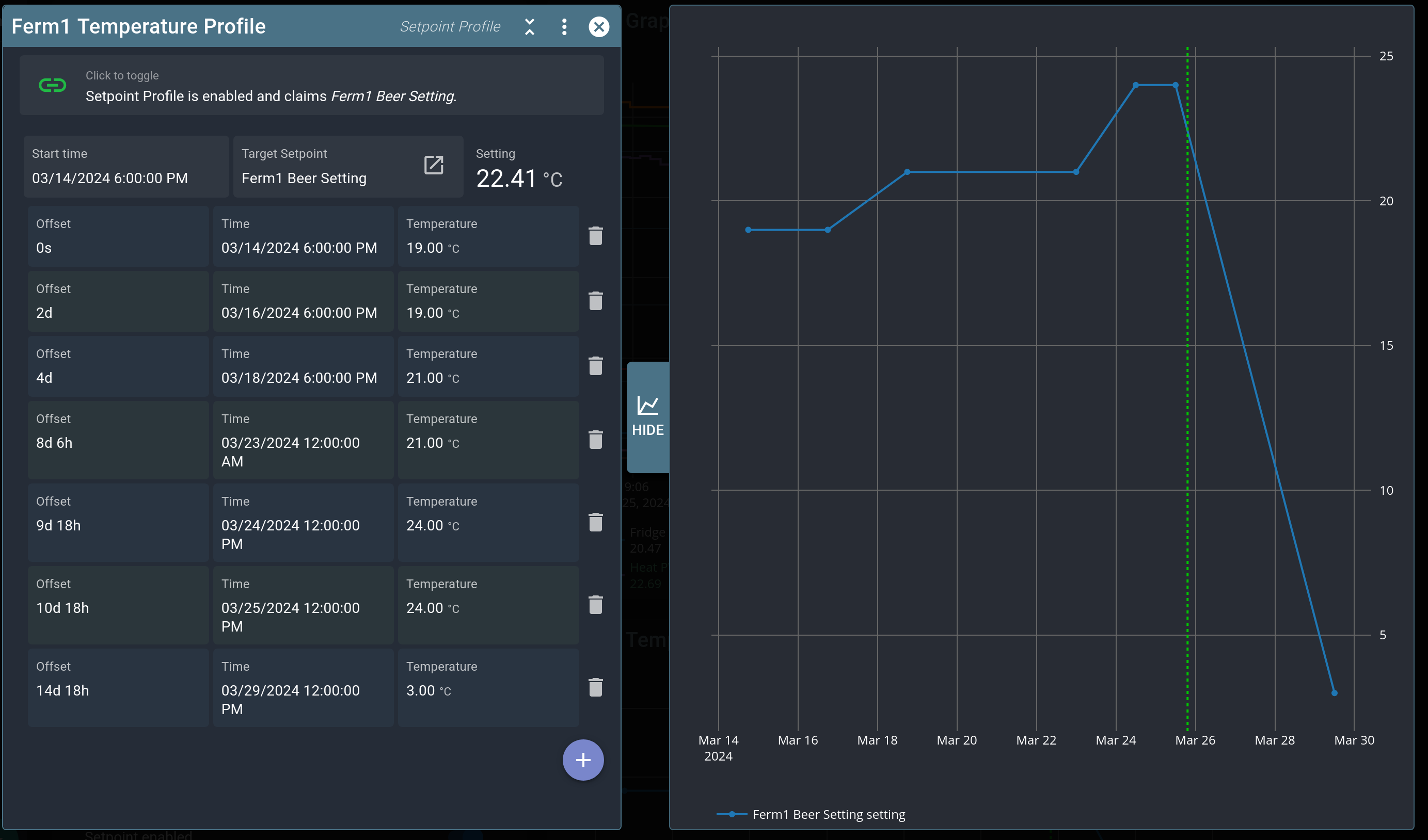

Fermentation Profile + Hopping

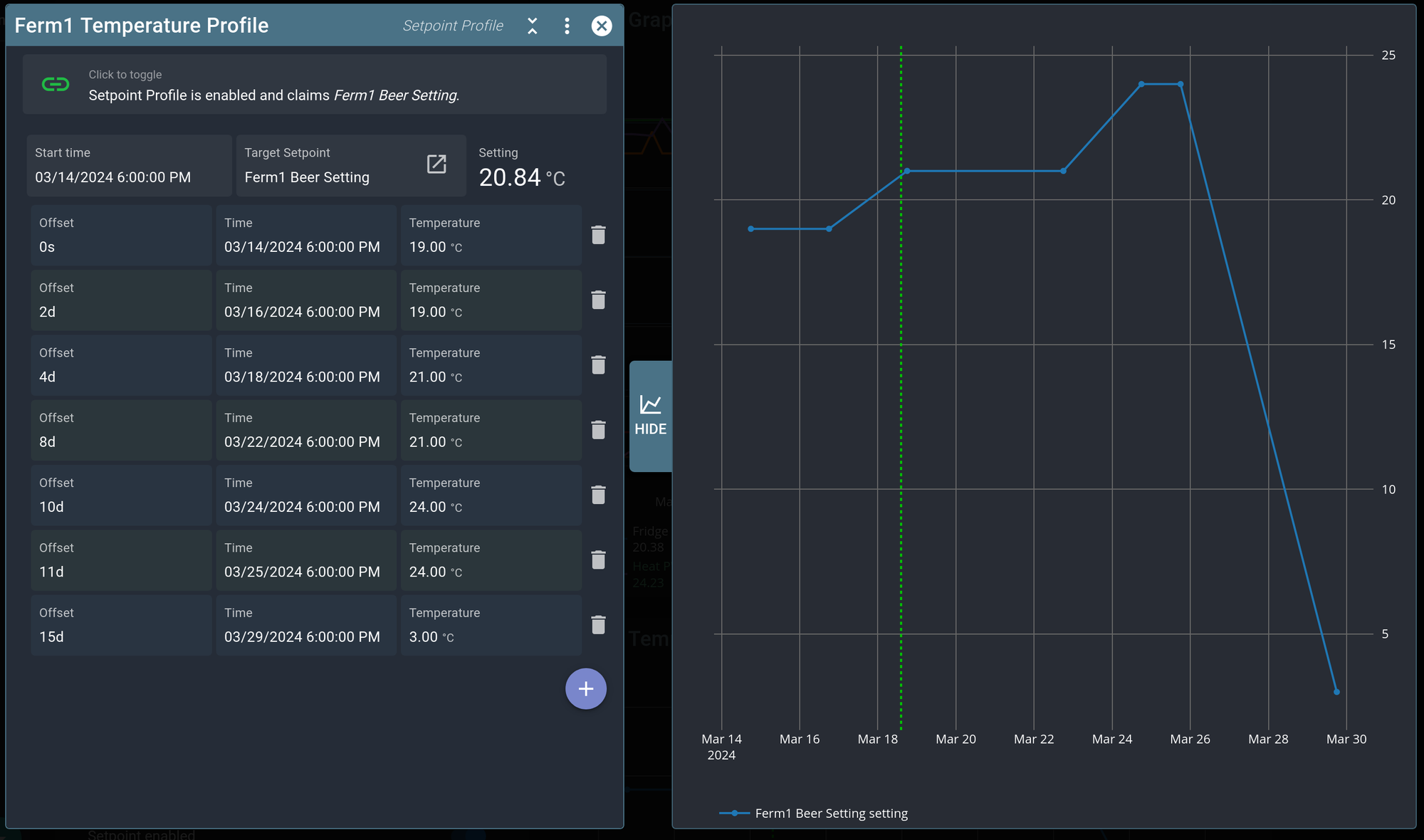

Using my temp controlled fermentation chamber I'm able to create a temperature profile in advance and just set and forget. For this brew I started with 48 hours at 19c, followed by a 2 day ramp up to 21. During this ramp I fit a spunding valve and starting at 7.5psi have been adding 1.5 psi per day until I get to 12psi. Once the temp is at 21 I'll leave it there until fermentation has finished which I've guessed will happen by day 8 below, though I can extend this easily with a few mouse clicks if I need to.

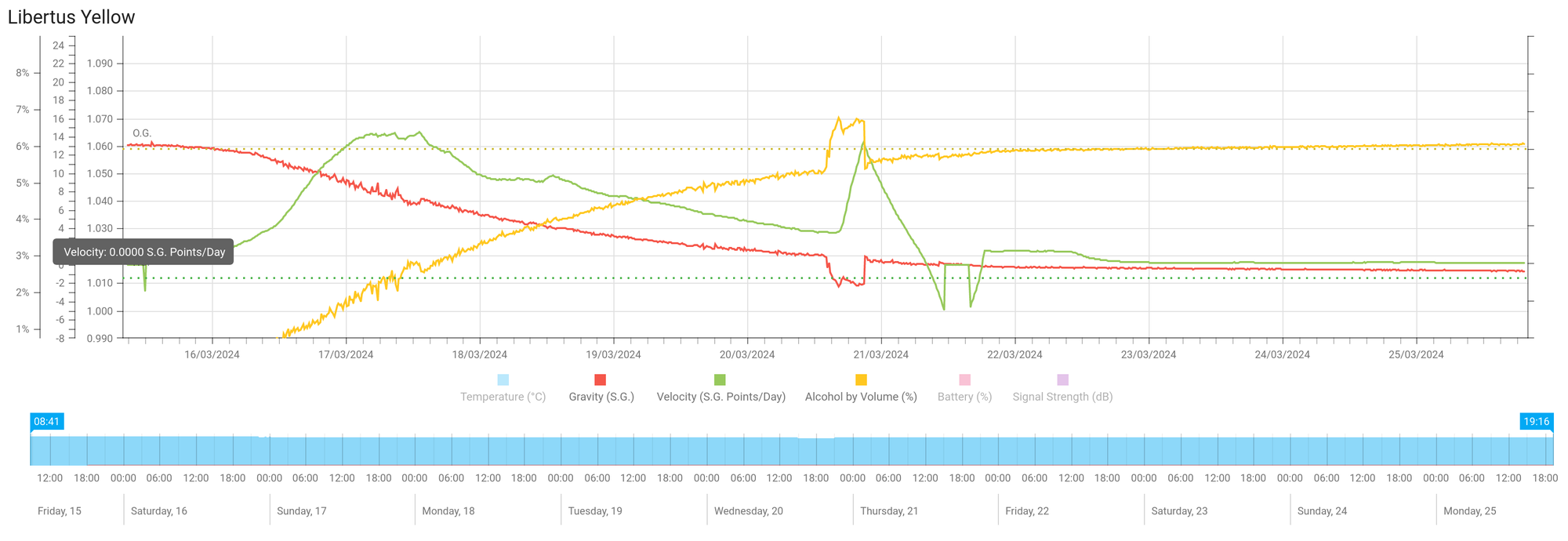

Around 1.020 or 5 points before the end I'll add the two dry hop additions and rouse daily for 3 days (I just gently shake the fermenter) by which time fermentation should have ended around 1.013/14. I keep track of the fermentation process velocity with my Rapt Pill as you can see below. When fermentation is over velocity goes to zero and the red gravity curve flattens out completely.

Update: Monday 25 March 2024

The Fermentation has been tracking well and the beer is now at the end as theres been no real change in the FG for 2 days now. The jump you can see in the curves below happened when I shook the fermenter one day as the RAPT pill ended up resting on the dip tube for a couple of hours until I shook it again.

As you can see in the temp profile below, we've come through the precautionary 24hour diacetyl rest, and are now starting down the 4 day crash cooling ramp which will have us finish this brew on Saturday at 12 noon.