Brewday 16/04/24 - Schofferhoffer Weizen IV

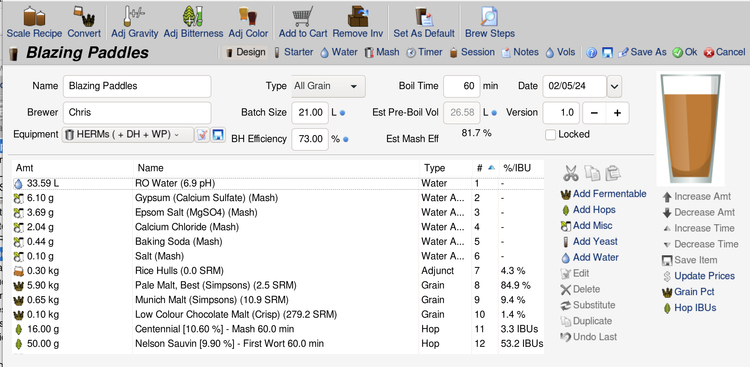

So with Blazing Paddles (8.3% abv) and Electric IPA (6.5% abv) now aging in my Keezer it seemed like a good time to brew a lower abv beer and I decided to have another crack at brewing the Schofferhoffer clone to see if I could replicate the 1st one I brewed in Nov 2022 which was quite simply amazing. Since then I've brewed it twice and they've been good, perhaps even really good, but not as good as that first one.

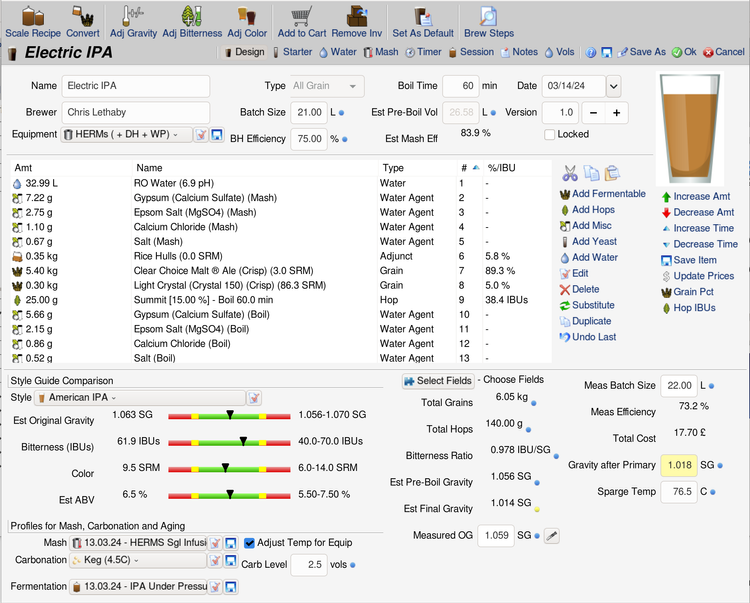

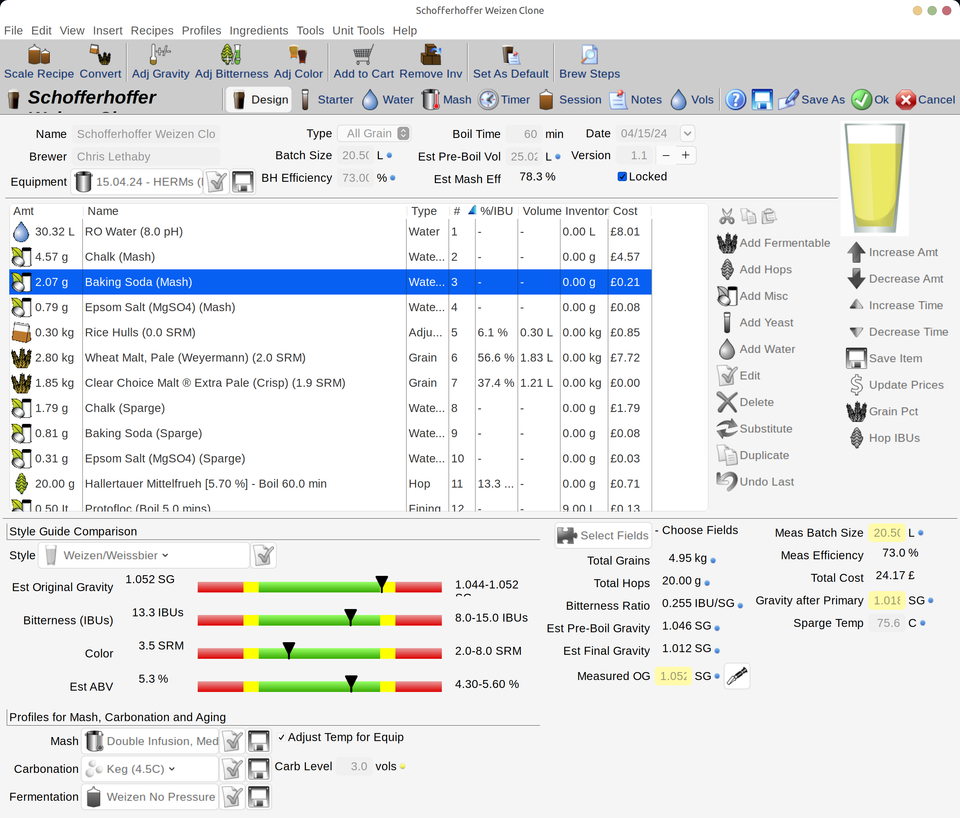

Recipe

I'm using the same recipe I've used each time but this time I'm fermenting with zero pressure again but using a dry yeast in the form of 2 x 11 g packets of WHC Lab's Banana Split. No late hops additions, whirlpool or dry hopping of course.

Target Batch size: 21.0 liters (into fermenter)

Brewhouse efficiency: 73%

Target OG: 1.046

Target FG: 1.012

Est IBUs: 13.3

Est ABV: 5.35

MALT/GRAIN BILL

2.8 Kg Weyermann's Wheat Malt (fine)

1.85 Kg Crisp's Clear Choice Extra Pale (fine)

0.30 Kg Rice Hulls

WATER PROFILE

Munich Germany

Profile: Ca=75, Mg=20, Na=10, Cl=2, SO4=10

HOPS & ADDITIONS SCHEDULE

20g Hallertauer Mittilfrueh - 60min (Boil)

YEAST

2 x 11g WHC Labs Banana Split

Brewday

My Brewday started the day before with making some RO water.

- 32 for the HLT which includes enough to cover the HERMS coil (approx 21l) and a further 10.74l of water to be drawn off for the Ferulic Rest while still keeping the HERMs coil covered so I can maintain mash temp. Later, I use this water for the Sparge after raising it to mash-out temp

- 11.5 l into the BK for the Saccharification rest, the second stage of the Mash.

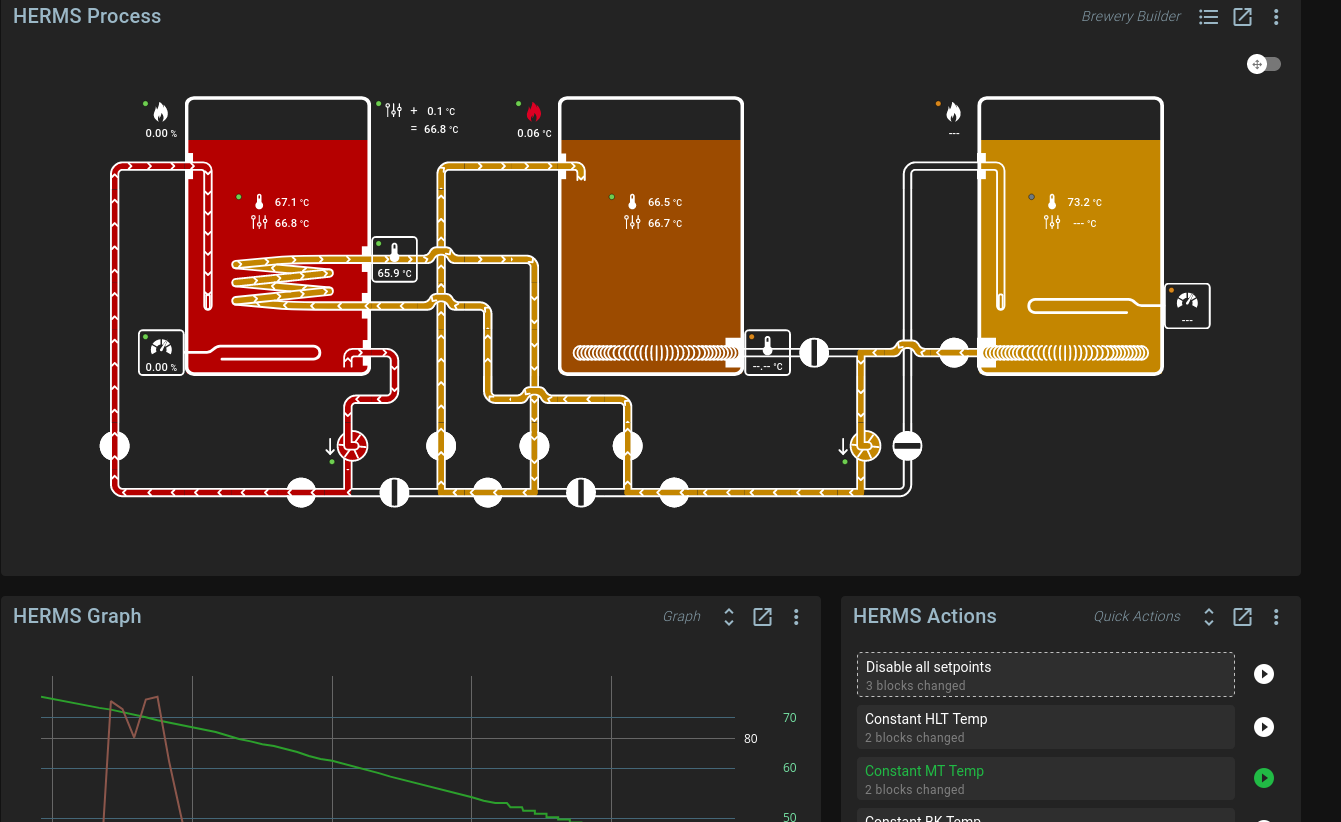

9am on I turned the power on and and set the target temp for the HLT to 52.2 degrees for the the initial 10.74 l of water used for the Ferulic Rest. I then set the BK to 92.7 degrees for the water I'd need later Sacharification rest.

I then set about working out the correct ratios of salts for each vessel of water.

Step Mashes in HERMs systems are a little complex !

Beersmith does a great job of calculating how much water is required for each stage of the brew and provides two sets of water addition tables accordingly, one for the Mash and one for the Sparge. Usually this is pretty simple because I heat the mash water in the BK and the Sparge water in the HLT which is also used for heating the HERMs coil until it needs.

This requires me to perform a very simple calculation to work out the ratio of actual HLT water to the recipe's required Sparge water and adjust the salts going into the HLT accordingly.

In this case it's a little more complex. I'm using the HLT for the Ferulic rest water at mash-in, then topping up the mash with with much hotter water from the BK to reach the full saccharification rest temp and volume for stage 2 of the mash, and then using the remainder of the water in the HLT to maintains mash temp through the herms coil and sparge with later.

The easiest way I'v found to work this all out is to add the Ferulic rest and Saccharification water volumes together to get the total Mash water and then divide each of the 'mash' water additions by that number to reach a gram per litre number for each addition and then simply multiply that by the total liters of water that are in the HLT and BK and then add the additions. This way, all the water is at the correct profile.

Mash In

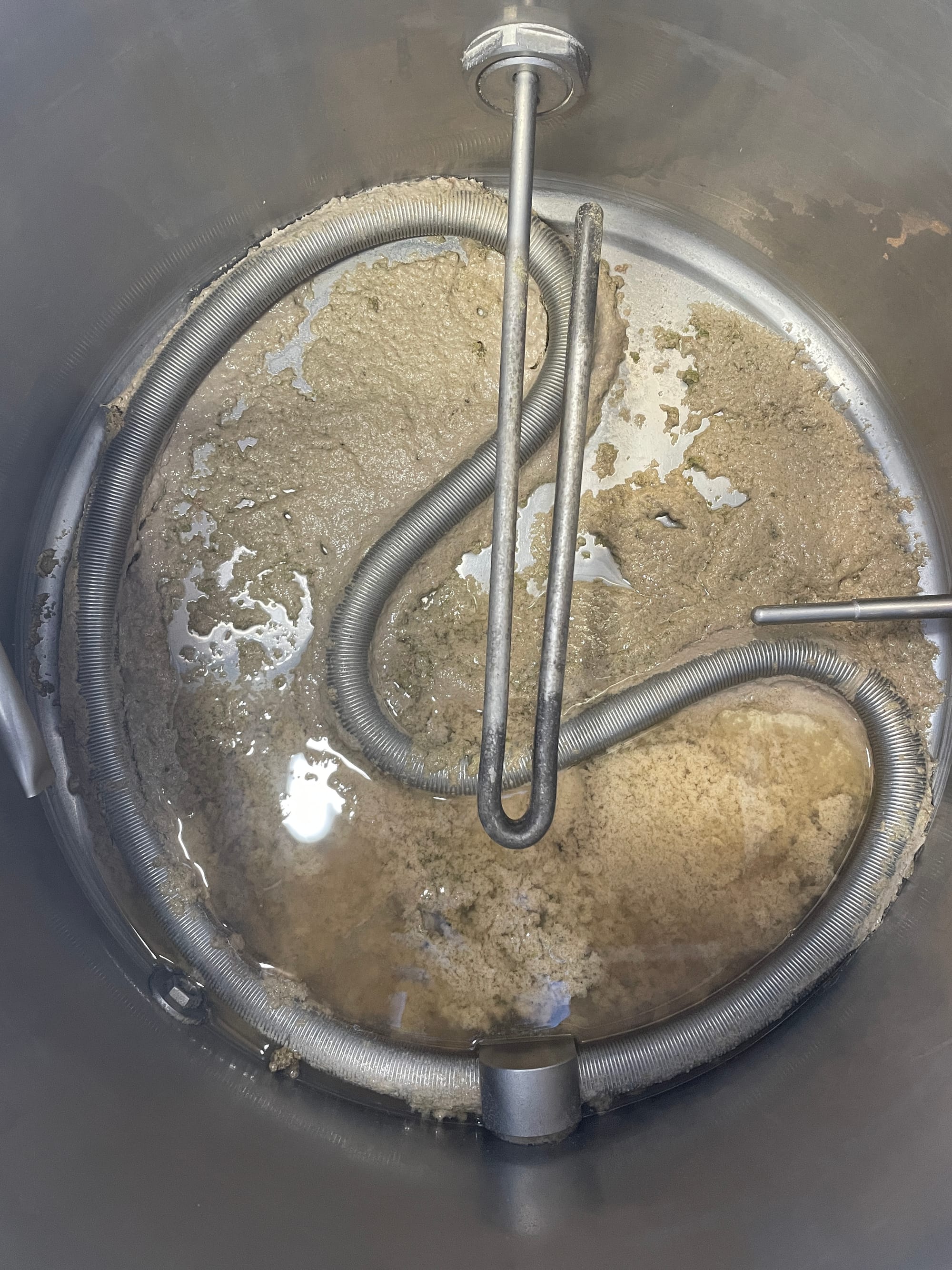

As I was doing a 2-Step mash I began the mash by under-letting the grain in the MT with 10.74l of water from the HLT before letting it have a Ferulic Rest for 20 minutes. While this was going on I began ramping up the remaining water in the HLT to 69 degrees, 2.3 above my target Saccharification temp of 66.7. I was also maintaining the water in the BK at 92.7 for the Saccharification stage.

It all went to plan and once I'd begun the Saccharification stage I lowered my re-circulation manifold into place and set the HERMs to take control of the Mash temp.

Once 60 minutes was up, I raised the Mash to mash-out temp via the HERMs process by increasing the target temp to 76c and then once the temp was close I stopped circulating through the re-circulation manifold and began draining the mash into the BK.

Once I get about 10l of mash in the BK, I fit the sparge arm and begin slowly sparging the grain bed.

Sparging

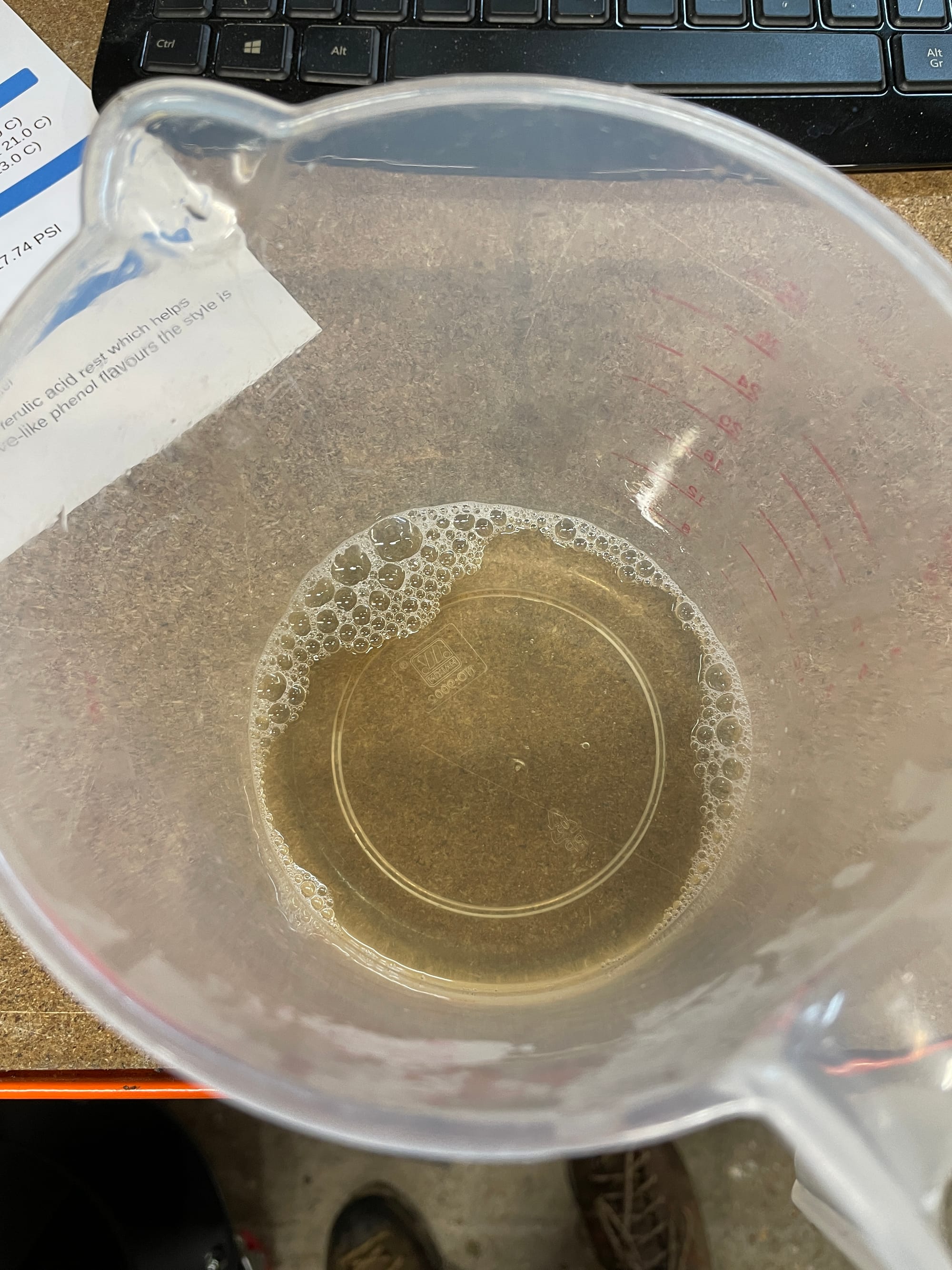

Following this we're on to the 60 Minute Boil using my brewzilla condensor arm and then I chill the wort down to pitching temperature using a counter-flow chiller, and finally place the fermenter into my fermentation chamber.

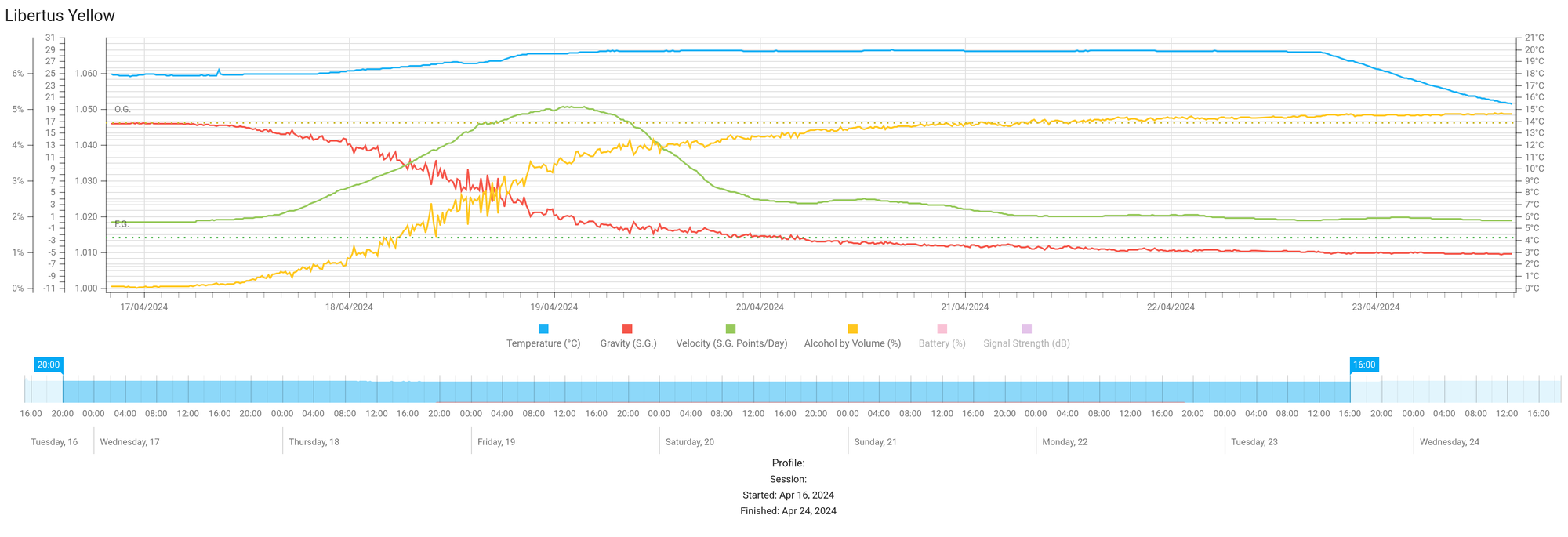

As you can see below the fermentation followed a predictable path with peak activity (green line) occurring 48 hours after pitching the yeast.

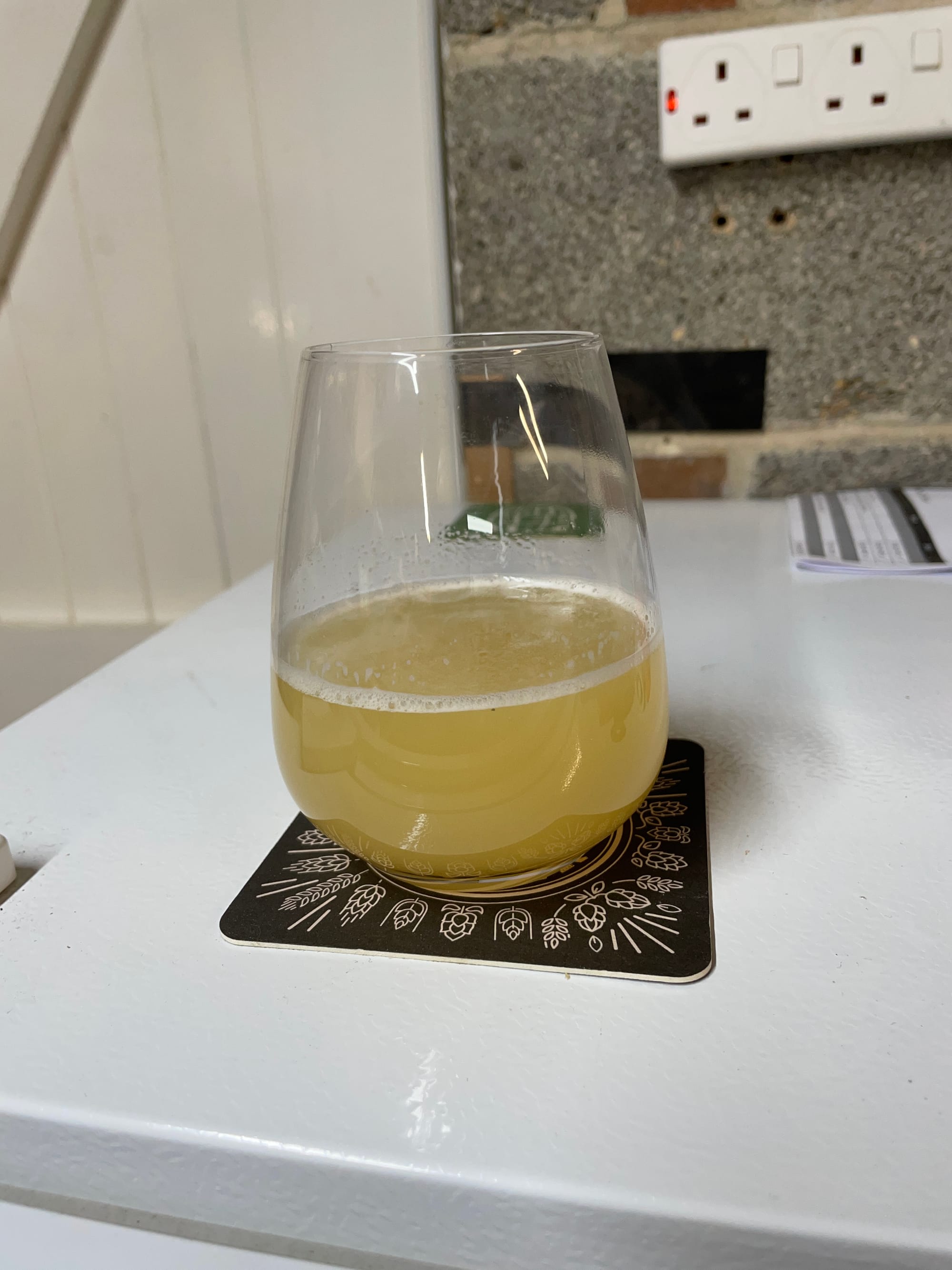

The finished product being kegged, carbonated and then poured for tasting.