After a 10 month hiatus due to discovering I had Oral Cancer last July, I brewed a 7.5 abv West Coast IPA today. I spent the entire week last week stripping down the brewstand, ferm fridge and keezer and meticulously cleaned every single component. I've also rebuilt the BrewPi Spark Brewery Controller with a fresh install of BrewBlox accompanied by re-base-lining the temp sensors (that were working), see that post for detail of that.

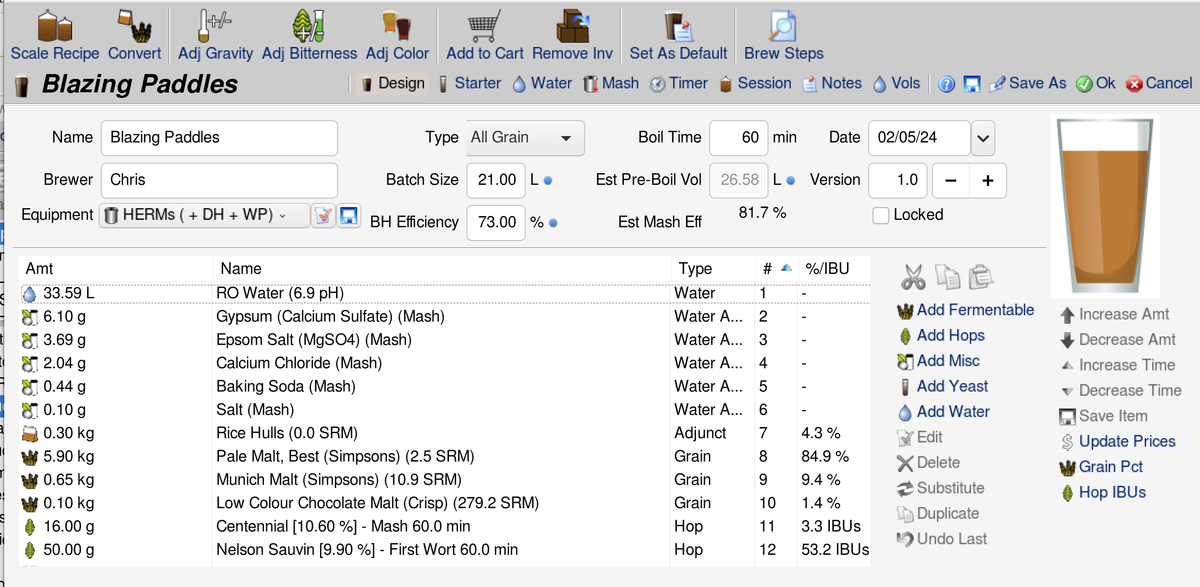

Recipe

I still had some hops that were perhaps 9 months old which I wanted to use, and two sachets of West Coast IPA yeast that I haven't tried before, so I adapted a West Coast IPA recipe to use these. They'd all been stored refrigerated and I'd given the hops a rub and they smelled ok, but I didn't necessarily want to use them as aroma hops so I used 16g of Centennial in the mash, followed by 50g of Nelson Sauvin in the boil as a bittering hop. I chose the Nelson Sauvin for bittering as opposed to the open Cascade in the picture below as it has relatively low cohumulone which gives a smoother bitterness than hops with higher cohumulone and the Cascade should work better with the Simcoe and Mosaic to make the finished beer true to the West Coast style.

ALL-GRAIN

Batch size: 21.5 liters (into fermenter)

Brewhouse efficiency: 73%

OG: 1.069

FG: 1.012

IBUs: 68.8

ABV: 7.5%

MALT/GRAIN BILL

5.9 Kg Simpsons Best Pale Malt

0.65 Kg Simpsons Munich Malt

0.10 Kg Crisp's Low Colour Chocolate Malt

0.30 Kg Rice Hulls

HOPS & ADDITIONS SCHEDULE

16g Centennial -> Mash [3.3 IBUs]

50g Nelson Sauvin -> First Wort [53.2 IBUs]

25 g Cascade -> 20 Min Whirlpool at 82C [2.2 IBUs]

25g Mosaic -> 20 Min Whirlpool at 82C [4.9 IBUs]

25g Simcoe -> 20 Min Whirlpool at 82C [5.2 IBUs]

50 g Cascade -> Day 2 of Cold Crash (~15C) for 2-3 days (roused regularly)

50 g Mosaic -> Day 2 of Cold Crash (~15C) for 2-3 days (roused regularly)

50 g Simcoe -> Day 2 of Cold Crash (~15C) for 2-3 days (roused regularly)

YEAST

Lallemand BRY-97 Americal West Coast Ale yeast - 2 x 11g sachets

Brewday

My Brewday had actually started the day before with making some RO water.

- 26 l for the HLT (enough to cover the HERMS) coil and then use 14l to sparge

- 21 l into the BK to mash in with

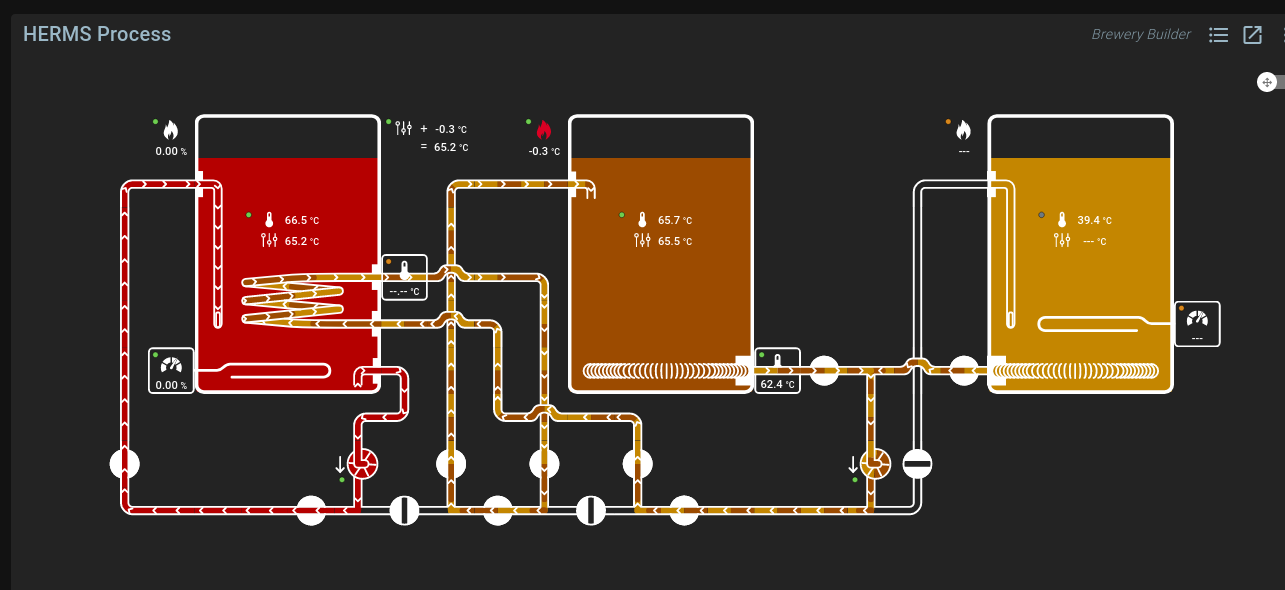

At 7am on Monday I turned the power on and and set the target temp for the BK to 74.2 degrees for the mash water, and 68.5 degrees for the HLT. This is 3 degrees higher than the recipe's mash temp as I wanted to be ready to use the HERMS coil to add heat if I undershot. If I overshot I had some cold RO water on hand to cool the mash down.

Mash-In

As it turned out I was only .2C over my my target temp of 65.5 (going for dryness) at mash-in so I moved ahead and took a pH measurement which was 5.6. I was aiming for 5.2 so did the calcs in BeerSmith and added 9ml of 88% Lactic Acid to the mash, and rechecked. It was 5.2 so I was happy. Note, you can see wort temp on the mash tun exit is 62.4 which gives you an idea of the gradient through the mash.

I then hooked up my new 12" Lautering manifold purchased from the Malt Miller and proceeded to lauter while running the mash through the HERMS coil to maintain temperature. After messing around and bodging up a hanger using my stainless steel paddle it worked really well.

Murphy steps in and it all turns to custard !!

So after an hour, the grain bed has settled, the wort is crystal clear and it's time to raise the temp to 76 C and mash out. After I set the MT target temp to 76 in BrewBlox, the PID looks at the ramp from 64.9 to 76 and adds the max differential of +10 C to that (see the 3rd PID in between the HLT and MT below). This sets the HLT target to 86 in the shot below which dials in the heater element PWM to 100% and the temp should start rising.

I don't have any more screen caps because I got rather distracted from here. 10 minutes after setting the MT target to 76 I looked at the screen again and something was wrong, the HLT temp was actually dropping. I then turned around and looked at Cab A and the light for the Heating Element was off. So was the light for the pump, and the pump had stopped too. WTF? I should have known when the mash was under 65.5 in the last step.

Realising there was no power I thought I'd blown a fuse, but a quick check of the breaker cabinet proved otherwise, they were all fine. Ok, so it must be the fuse in the plug, so I go into the laundry, turn off the dryer, pull it out from the wall, and check the plug. It looks fine too.

Ok, try the wall switch. Nope. Try Cab A's main switch, nothing. 10+ minutes have gone past now and the HLT temp is still dropping, it's 63C now, and I need to move ahead so make an executive decision to skip the temp rise and just mash out, which is what I do, and as soon as I have 12l in the Boil Kettle I turn the heating element on and start bringing the wort to a boil. After 6-7 minutes I've completely emptied the mash tun and now start to sparge with a 1l plastic jug taking the 63 C water from the HLT. In the end I slightly overshoot my target boil vol by 1l and end up with 27.8 l in the boil kettle.

Overall, my mash was extended by about 30 minutes in total and my sparge was compressed into about 10-15 minutes. Not great.

- Sparge runnings gravity was 1.021 (slightly lower efficiency than ideal)

- BK SG was 1.0.58

So what broke?

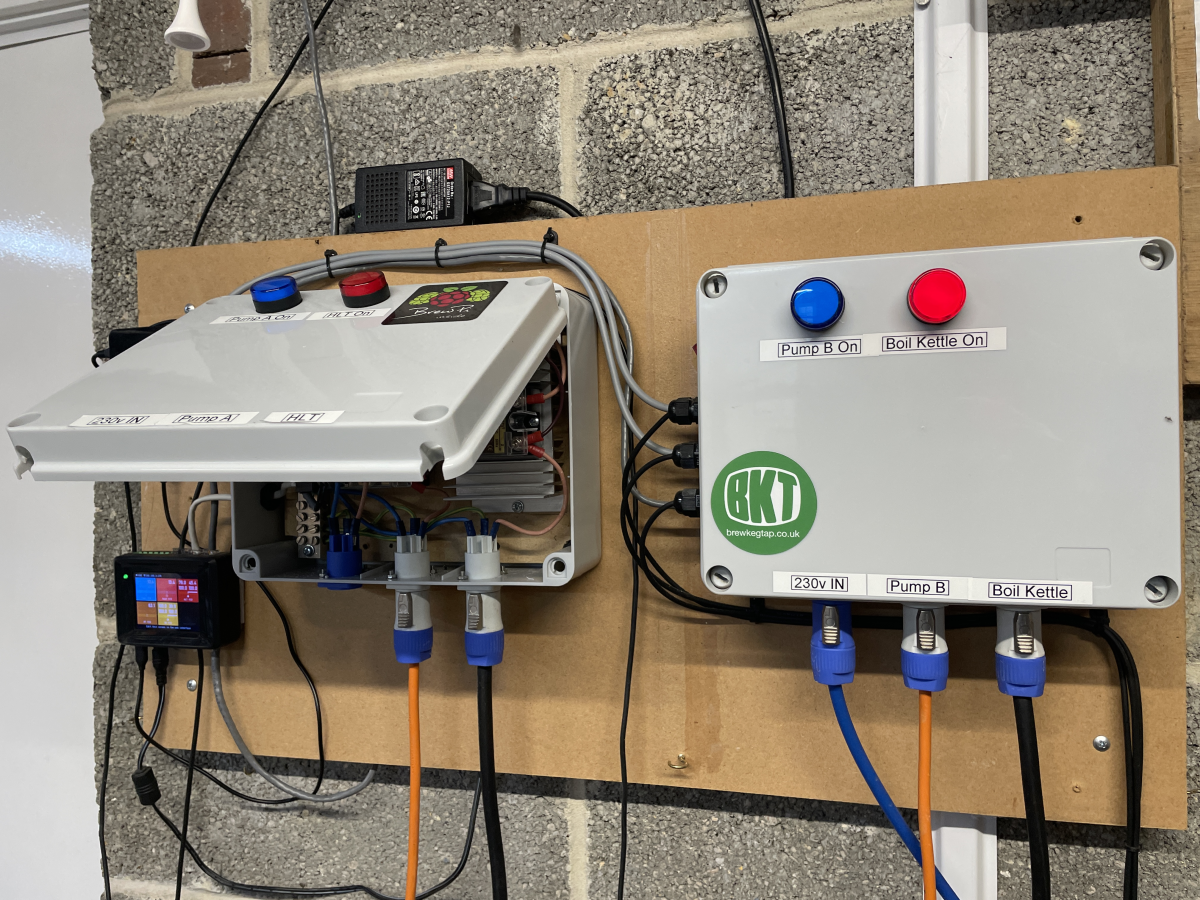

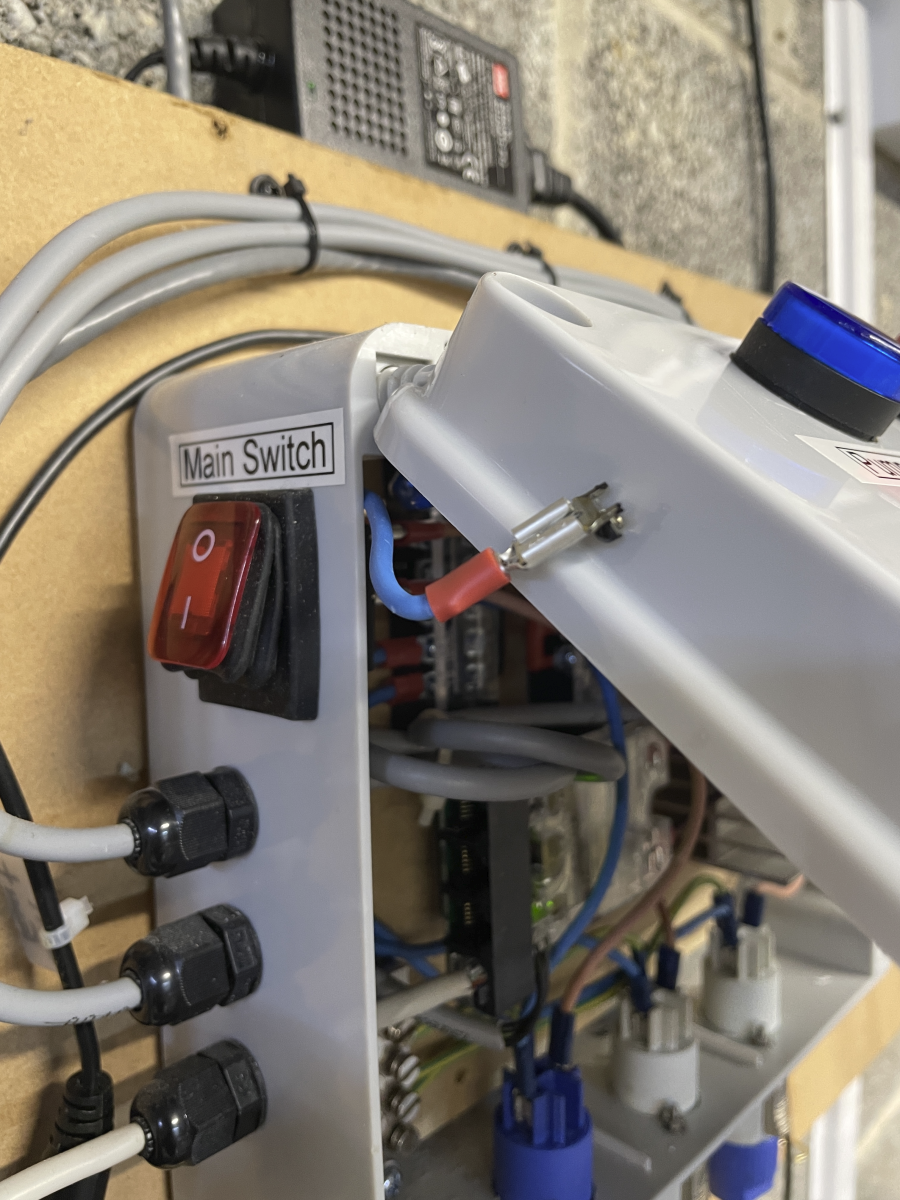

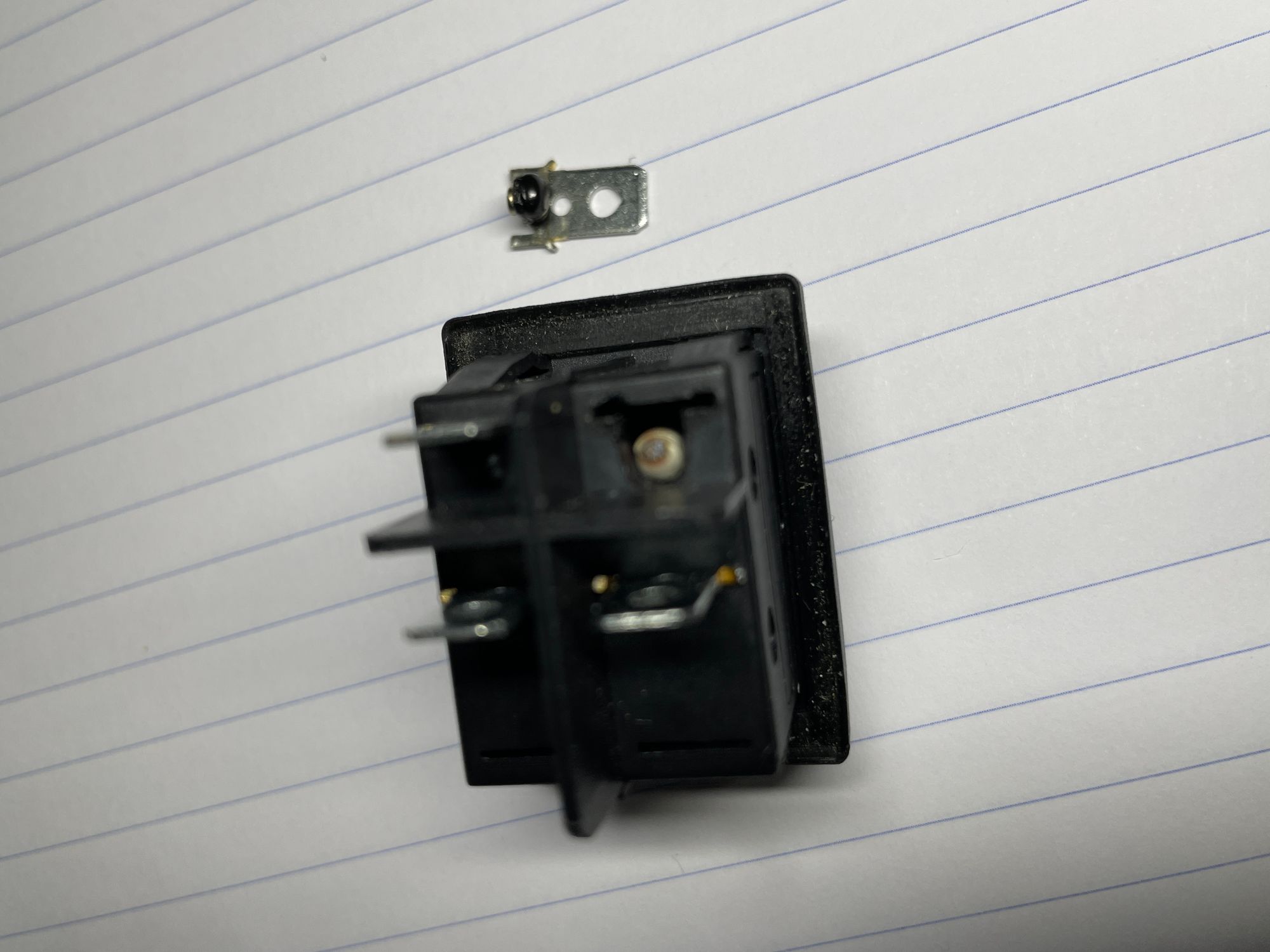

Once the boil was underway I turned my attention back to the power loss at Cab A. After scrambling around and tracking down my circuit tester, I eventually found the problem, the main switch on the cabinet had failed. These are supposed to be rated at 16A. Look very closely at the photos and you'll see that the bayonet and contact are retained in the plastic body by a piece of plastic that is perhaps 3mm round and .6mm thick.

Once the element was on at 100% with the pump running, I'd guess I was drawing close to 13.5A though that switch so it would have been pretty hot, melted and the bayonet/contact assembly just fell out.

As it happened I had a spare switch (non water proof) laying around which I quickly swapped into place and was back up and running in 15 minutes.

Testing my new Steam Condenser

In the past, I've brewed in my garage with the door open which rolls back horizontal directly above the boil kettle and collects condensation. This year I fitted a diesel heater to my garage so I could raise the temp a few degrees and decided that the only sensible way to brew would be with a steam condenser to prevent condensation forming everywhere and/or brewing with the garage door open again. So I bought one from BKT in their new year sale in Jan and tested it 2 weeks ago.

With a total of 3.3l extra vol to boil off I decided to boil a little more vigorously than I usually do in an effort to evaporate back to my fermenter target of 24.5.

After 1hr and 10 min I hit 24.5, added 1/2 a Whirlfloc tablet for 5 min via the condenser tube and then shutdown the boil. I then opened the lid to discover a thick ring of hot break stuck to the sides and lid of the kettle.

Putting my Brewzilla Condenser through it's paces

Cooling and Whirlpool

I don't have an Immersion Chiller so in the past I've attempted to use my counterflow chiller to cool the wort to 82 C before commencing my 20 Min whirlpool, but every time I've done this I've overshot considerably so now I just start whirlpooling with the lid off and let the wort cool naturally. This is not ideal and takes 20+ minutes or so to drop to 82 even in the 12 degree temp inside my garage.

There are no photo's of the whirlpool as I put the lid back on to conserve heat.

Counterflow chill into Fermenter

This is all pretty straightforward, I'm running cold tap water through the counterflow and slowly pumping the wort out into the Fermzilla All-rounder.

- OG 1.076 - Overshot

- Temp into fermenter = 16 C (overchilled, want 19 to pitch into)

Good results considering the drama

Pitching the Yeast

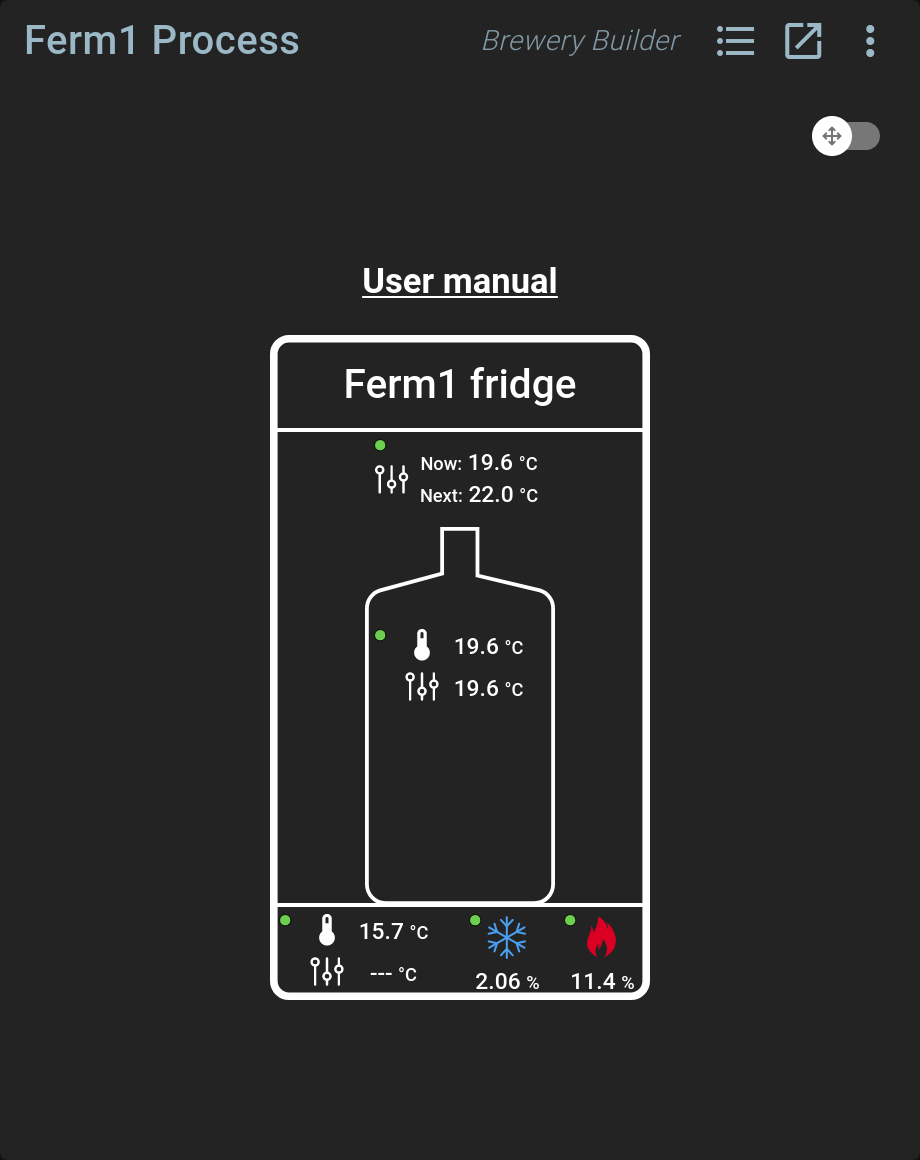

After moving the all-rounder to my Fermentation fridge, I then set the Ferm target temp to Beer and set the target temp to 19. At about 7:30 that evening when it hit 19 I pitched the yeast.

I then created a temp profile in BrewBlox which will control the temp as follows:

- 1 day at 19 C with just a bubbler to kick off Stg 1

- 5 days rising from 19 to 22 - spunding valve fitted after 36 hours @ 5 PSI and raised 1 PSI per day to 10 PSI

- 2 days at 22 C (diacetyl cleanup)

- 3 days crashing to 3.5 C (I'll dry hop on day 2 of the cold crash and leave until the end)

- 2 days conditioning

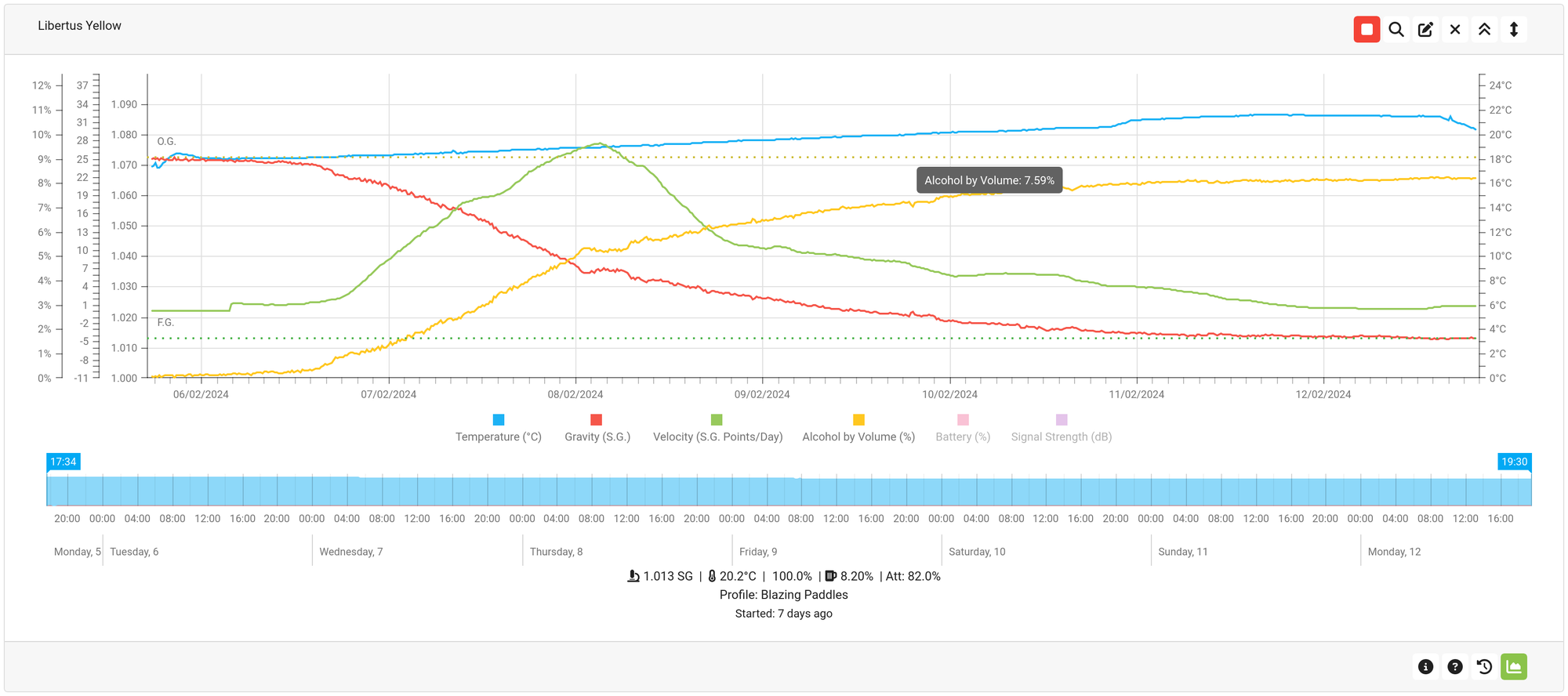

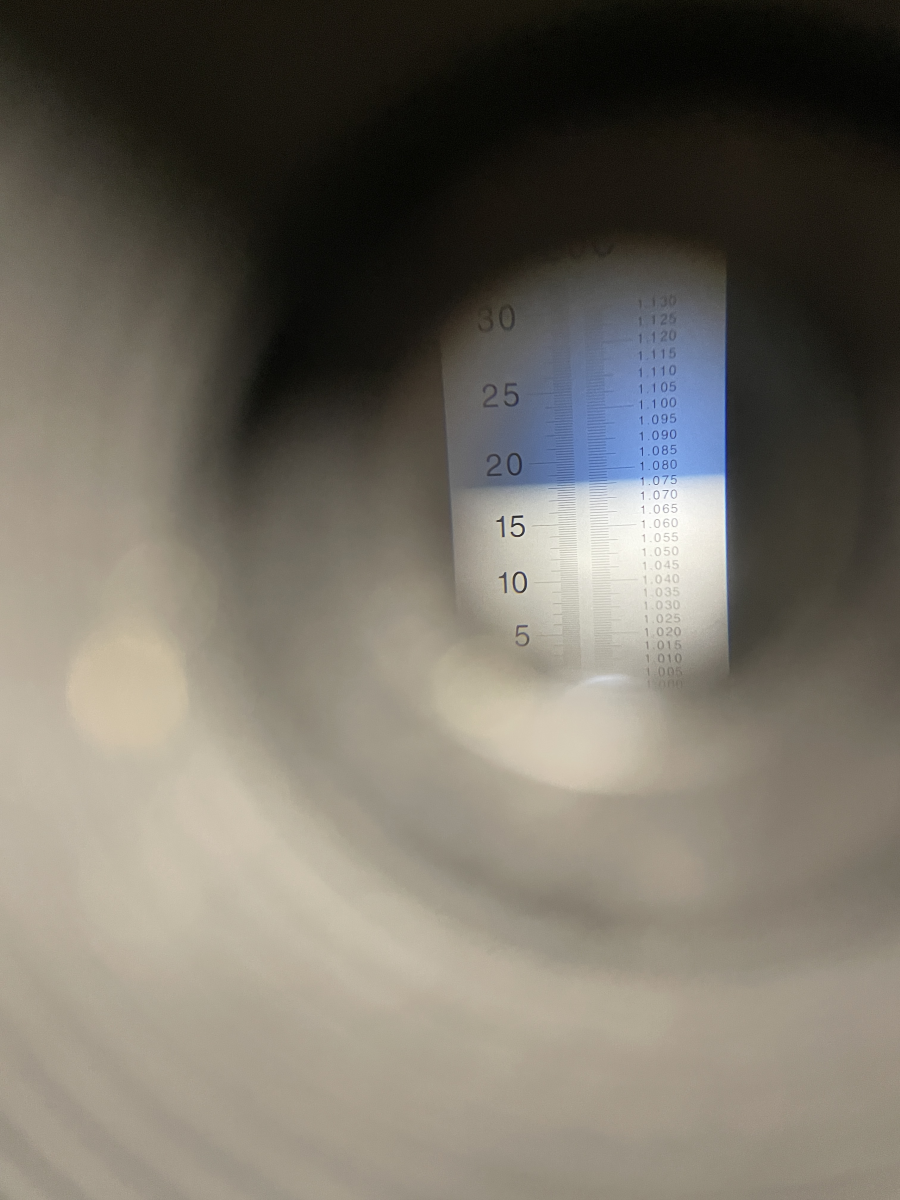

I'm also monitoring the fermentation with my Brewzilla Rapt which I use to track SG throughout the process. As soon as it indicates 1.020, I'll ramp up to 22 regardless of what day it is and then wait until it stops falling or hits 1.008 when I'll start the cold crash. The timeline is all down to the yeast vitality.

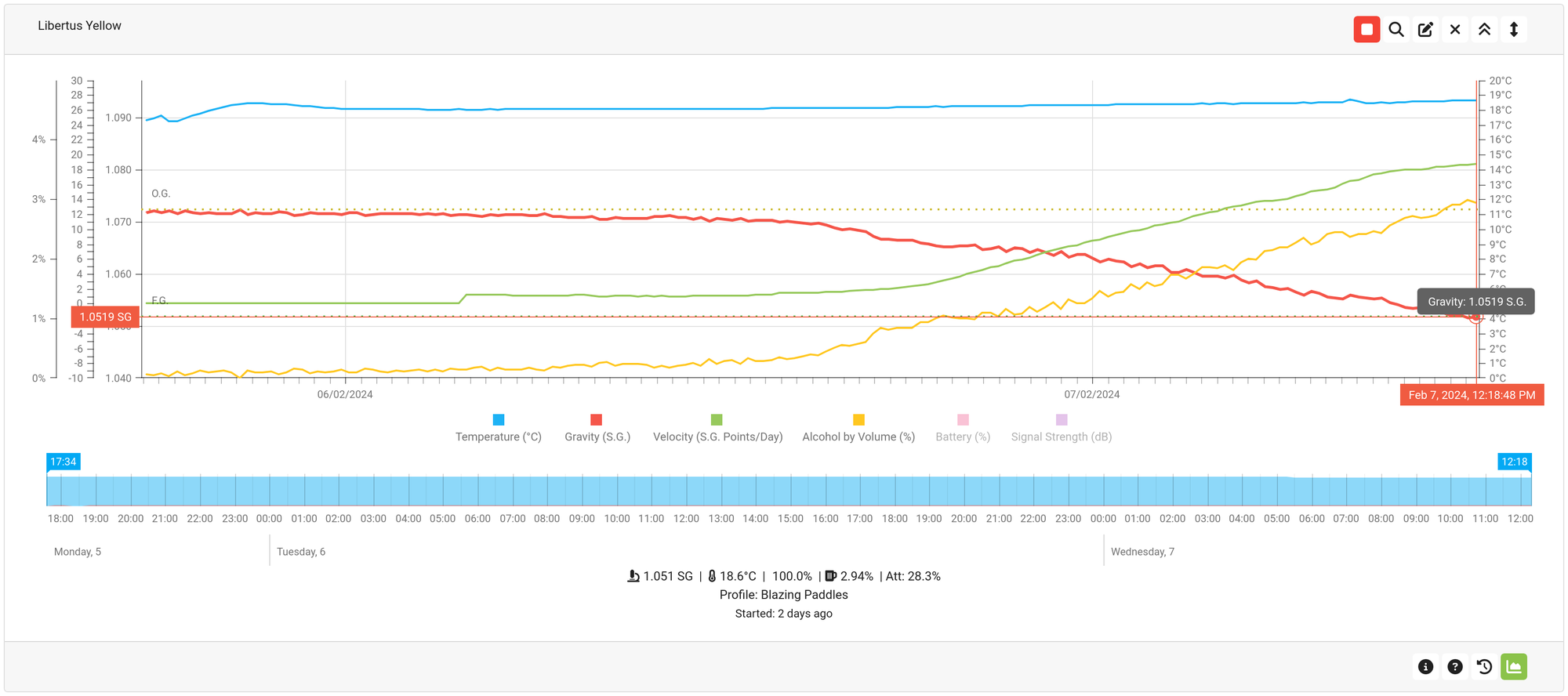

Update 3:51 PM Tuesday 6th Feb 2024

Less than 24 hours later, fermentation has kicked off nicely.

Update: 1.00pm Wednesday 7th Feb 2024

You can see that as I write this 2 days later (Wednesday morning) that the temp is 19.6 C on it's road to 22 (see fermentation profile above) and the SG has dropped 20 points from 1.073 to around 1.052 already.

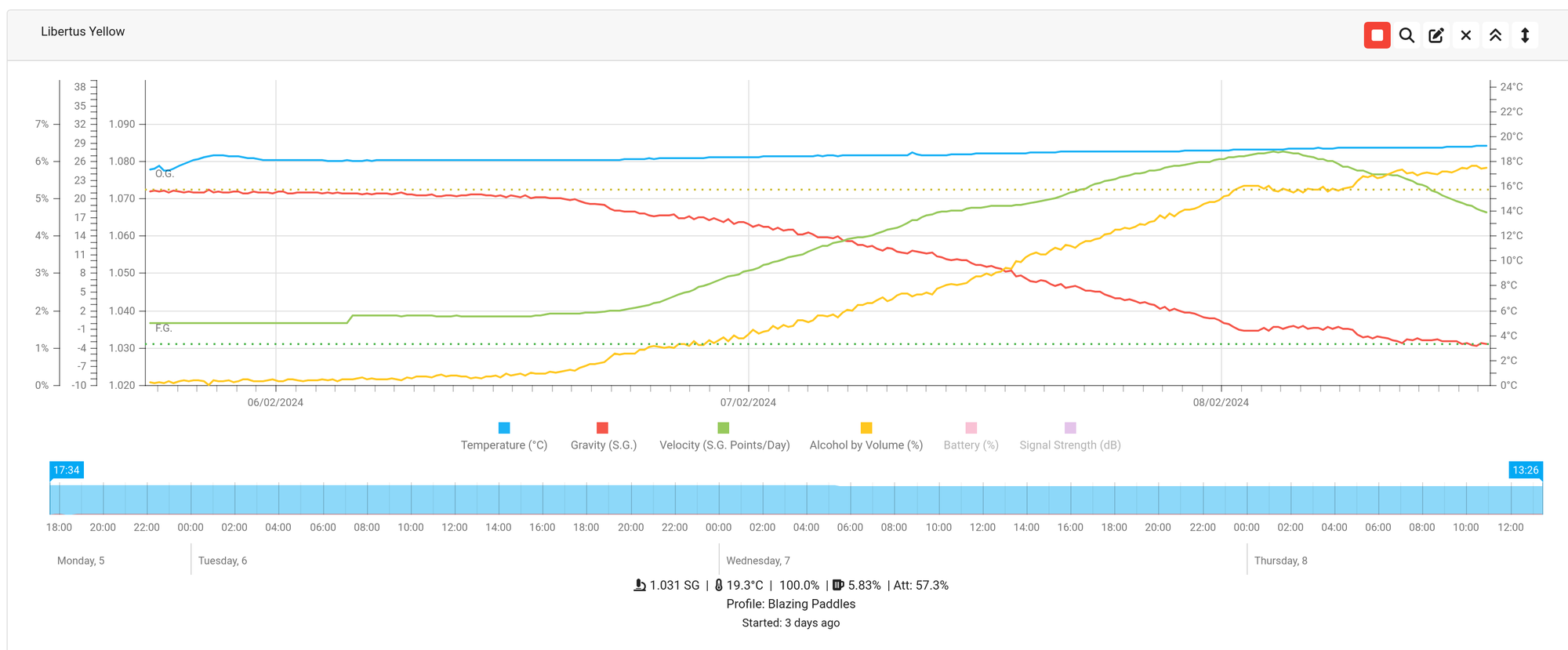

Update: 1:30pm Thursday 8th Feb 2024

Fermentation has been rocketing over the last 24 hours. You can see the green line in the RAPT graphs above and below which is tracking the fermentation velocity that it peaked at 27 SG point per day at 2am this morning. From that peak the velocity has started to dip but we're less than 3 days into fermentation and we're already at 1.031 (from 1.074 OG) so I'm pretty happy with that. Opening the fridge door it smells fantastic so I can't wait to dry hop once fermentation finishes.

I also bumped pressure up to 7psi as I'm aiming to finish around 12 so it looks like I'll need to add 2 psi per day.

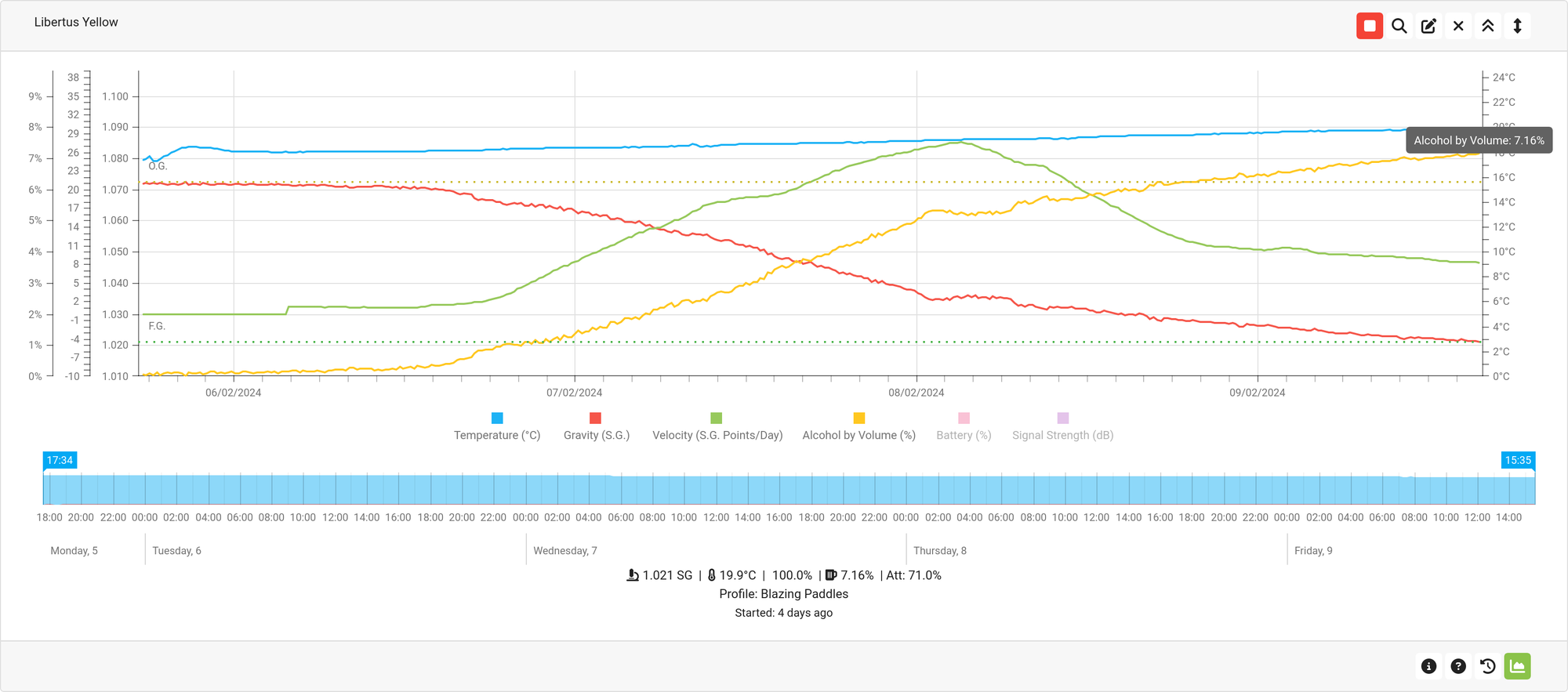

Update: 3:00pm Friday 9th Feb 2024

Fermentation has slowed to 8.2 SG points per day but is now 1.021 so with only 11 points to go to reach a FG of 1.010 it could be all over by Saturday evening/Sunday morning. From there I'll ramp up the temp to 23 (currently 20.8, see graph below) and give it another 24 hrs to finish off the diacetyl rest and then start the cold crash followed by Dry Hopping on Monday evening. Pressure is 10.6 psi.

Update: 8:00pm Friday 9th Feb 2024

Gravity hasn't changed for 36 hours so I'm going to call it done at 1.013. This equates to 82% attenuation and 8.20 % ABV.

It's Done